You are here: Home // Window A/C Unit That’s Less Than 6 Inches Tall

This post may contain affiliate links or mention our own products, please check out our disclosure policy .

Window A/C Unit That’s Less Than 6 Inches Tall

Published on May 23rd, 2016 by Ching Fu

Finally there’s a window air conditioner unit that is small enough in size and not a total power hog to use in an RV. Meet the newest window AC unit on the market – Noria !

Perfect window AC unit for a variety of small spaces.

Noria is still in its Kickstarter fundraising stage, but it’s already secured double the funding goal. It will retail for $400, but there’s an early bird special for a bit cheaper. With so many great features that meet the needs of people living in apartments, tiny homes, RVs, and regular houses, it’s not surprising that this unit is getting so much attention.

Noria comes with an adapter to easily fit in a variety of window sizes.

Instead of the awkward size and weight of regular window AC units, Noria was designed to be low profile and lighter. Noria weighs approximately 30 lbs and is sized at 5.8″H x 18.25”W x 15”D, compared to standard window units with the same cooling capacity that weigh 45 lbs and are 12″H x 15″W x 14″D.

DON’T MISS OUT ON DO IT YOURSELF UPDATES

Sign up for the newsletter today.

Please enter a valid email address.

An error occurred. Please try again later.

Thank you for subscribing to the Do It Yourself RV newsletter, keep your eye on your inbox for updates.

The new A/C comes with a window adapter so it easily fits into a window measuring 21” to 36” wide. It’s quick and easy to install the adapter, which goes in first, and creates a secure, sealed frame for the air conditioner to slip and lock into.

Not only is it good looking, but its low profile makes the unit easy to store.

To make the installation even easier, Noria is designed with a handle and rounded corners. Unlike traditional window units that fill up an entire window space, Noria is less than 6” tall so you keep the view from your window. Storage looks a lot easier, too.

Noria uses a refrigerant that’s environmentally and ozone-friendly. This window unit has a 5,000 BTU/hour cooling capacity which will cool a room up to 160 sq. ft. Drawing 460 – 480 watts, it’s totally usable in RVs via a generator, RV battery bank or large solar set up .

Easy-to-read interface.

The intuitive interface consists of a single knob that controls the most important thing: the temperature. Noria can also be set to a schedule via an iOS and Android app, letting you come home to a cool space without using more electricity than needed. During cool evenings, Noria’s fresh air mode can be selected to bring fresh air in from the outdoors.

Control Noria from the palm of your hand.

Its concealed fans, ventilation system and compressors makes Noria a lot quieter than traditional window units. Measured at 50 dB, Noria is about as loud as a moderate rainfall. There’s also a night mode with dimmed lights, so there’s no more blaming the A/C unit for a bad night’s sleep.

This modern and minimal AC unit is great for RVs! It uses a lot less power than roof top AC units that come with most camper models. R emoving a rooftop AC would free up valuable RV roof top space so you could fit an additional solar panel. And it weighs a lot less than roof top units – and window units for that matter.

On top of all that, you get to keep the incredible view out your window!

To learn more, visit this Kickstarter page . Here’s a video showing the Noria in action:

https://youtu.be/nktasCqHjzg

Share this post:

Related posts:.

Is Your RV AC Freezing Up? Here’s What To Do

The Number One RV Soft Starter Is Now 40% Smaller

Is Your RV AC Leaking Water? Here’s What To Do

AC All Solutions

Blog by Skilled About Air Conditioners

Rv Air Conditioner Window Unit: Stay Cool on the Road

Yes, you can install a window AC unit in your RV to ensure efficient cooling and heating for a variety of small spaces. Whether you have a compact camper or a spacious motorhome, a window AC unit can be a perfect custom cooling solution.

RV air conditioners are designed to run for as long as they are connected to a power source, making them suitable for continuous use when connected to residential shore power or a generator.

Portable AC units with smart features offer flexibility for cooling small spaces within your RV where a window AC unit may not fit, ensuring you can stay comfortable on your travels.

If you’re looking for a replacement or nearby RV air conditioner window unit, there are various options available, including the Dometic RV air conditioner window unit and installation kits for RV window AC units.

Table of Contents

Choosing Your Rv Air Conditioner Window Unit

When selecting an RV air conditioner window unit, there are several factors to consider to ensure optimal cooling efficiency and compatibility with your RV.

From assessing the importance of the right cooling system to understanding your RV’s specifications and space constraints, here’s a guide to help you make an informed decision.

Importance Of The Right Cooling System

Choosing the appropriate cooling system for your RV is crucial in maintaining a comfortable and enjoyable travel experience. A well-suited air conditioner window unit will not only keep the interior cool during hot weather but also contribute to energy efficiency and reduced overall operational costs.

Furthermore, with the right system, you can ensure that your RV’s electrical system can adequately support the air conditioner’s power requirements, minimizing the risk of electrical issues while on the road.

Understanding Rv Compatibility

Before selecting an RV air conditioner window unit, it’s essential to consider the compatibility of the unit with your specific RV model. Factors such as the size of the RV, the layout of the interior space, and existing electrical infrastructure need to be taken into account to ensure a seamless installation and optimal performance.

Additionally, understanding the ventilation requirements of your RV will help in determining whether a window air conditioner unit is the most suitable option for your vehicle.

Assessing Space And Power Requirements

Space and power considerations are fundamental in selecting the right window air conditioner unit for your RV. Assessing the available space for installation, as well as the power capacity of your RV’s electrical system, will help in determining the appropriate size and cooling capacity of the unit.

By considering these aspects, you can ensure that the air conditioner not only fits seamlessly within the designated area but also operates efficiently without overloading the electrical system.

Features Of The Perfect Rv Window Unit

When it comes to selecting the ideal RV air conditioner window unit, there are several key features to consider. From energy efficiency to innovative technology, the perfect window unit should cater to the specific needs of RV enthusiasts.

Let’s delve into the essential features and considerations to keep in mind when purchasing an RV air conditioner window unit.

Key Considerations For Purchase

Purchasing an RV air conditioner window unit involves several key considerations to ensure optimal performance and compatibility with your specific RV setup.

Some of the vital aspects to keep in mind include the size of your RV, the available window space for installation, power requirements, and the unit’s cooling capacity. Additionally, considering the unit’s weight and dimensions is crucial to ensure it fits seamlessly within your RV’s space constraints.

Highlighting Energy Efficiency And Btu Needs

Energy efficiency is a paramount factor to consider when selecting an RV air conditioner window unit. Opting for an energy-efficient unit not only reduces power consumption and operational costs but also contributes to environmental sustainability.

It’s essential to assess the BTU (British Thermal Unit) needs of your RV to determine the appropriate cooling capacity. Finding the right balance between energy efficiency and cooling power ensures optimal comfort while minimizing energy wastage.

Innovative Features And Smart Connectivity

Modern RV air conditioner window units are equipped with innovative features aimed at enhancing user experience and convenience.

From smart connectivity options, allowing remote control via smartphone or tablet, to advanced climate control settings for customized cooling preferences, these cutting-edge features elevate the comfort and functionality of the unit.

Additionally, features such as sleep mode, programmable timers, and adjustable airflow contribute to a tailored and efficient cooling experience for RV enthusiasts.

Installation Insights For Window Ac In Rvs

When installing a window AC unit in your RV, follow these steps to ensure a smooth setup:

- Choose a suitable location for the AC unit and measure the window opening to ensure compatibility.

- Secure the AC unit in place using brackets or a mounting kit that is specifically designed for RV installations.

- Carefully position the unit in the window and secure it to prevent any movement while the RV is in motion.

- Connect the power supply to the AC unit and test for proper functionality.

Here are some tips to consider when installing a window AC unit in your RV:

- Ensure that the window opening can support the weight of the AC unit and make any necessary reinforcements if needed.

- Use weather-stripping or foam insulation to seal any gaps around the AC unit to prevent air leaks and maintain energy efficiency.

- Regularly inspect the mounting brackets and connections to ensure they remain secure during travel.

- Consider consulting an RV technician if you are unsure about any aspect of the installation process.

When undertaking a DIY installation of a window AC unit in your RV, it is essential to have the following tools and materials on hand:

Maintaining Your Rv Air Conditioner

Keep your RV window air conditioner in top shape by regularly cleaning the filter and coils, ensuring optimal airflow and performance. Schedule annual professional maintenance to inspect and clean the unit’s internal components, preventing potential issues and extending its lifespan.

Regular maintenance helps your RV air conditioner operate efficiently and keeps your space comfortable during your travels. Maintaining Your RV Air Conditioner. Routine maintenance for longevity

Proper maintenance is essential in keeping your RV air conditioner running efficiently. Regular maintenance can extend the lifespan of your unit and ensure it operates at its peak performance. Here are some essential routine maintenance tasks to keep your RV air conditioner in top condition:

– Clean the filters : Clogged or dirty filters can reduce the efficiency of your air conditioner and strain its components. Regularly clean or replace the filters to ensure optimal airflow and cooling performance. – Inspect the fins and coils : Over time, the condenser coils and fins can accumulate dirt and debris, hindering heat transfer. Periodically clean these components to maintain efficient heat exchange and prevent overheating. – Check the seals and gaskets : Inspect the seals and gaskets around the unit to ensure they are intact and free from damage. Tight seals are crucial for preventing air leaks and maintaining proper insulation.

Troubleshooting common issues

Despite regular maintenance, your RV air conditioner may encounter common issues that require attention. Understanding and addressing these issues promptly can prevent further damage and ensure continuous comfort during your travels. Here are some common problems and their troubleshooting tips:

– Poor cooling performance : If your air conditioner is struggling to provide adequate cooling, check for airflow restrictions, dirty filters, or refrigerant leaks. Clear any obstructions and clean the filters to improve performance. – Unusual noises : Strange noises such as rattling, grinding, or squealing can indicate a problem with the fan, motor, or other internal components. Inspect the unit for loose or damaged parts and seek professional assistance if needed. – Water leaks : If you notice water leaking from your air conditioner, it could be due to a clogged drain line or improper unit leveling. Clear any blockages and ensure the unit is properly positioned to prevent leaks.

When to seek professional help

While regular maintenance and troubleshooting can address many issues, some problems may require the expertise of a professional technician. If you encounter the following issues, it’s time to seek professional help:

– Refrigerant leaks : Handling refrigerant requires specialized knowledge and equipment. If you suspect a refrigerant leak, contact a professional technician to locate and repair the leak, and recharge the system. – Electrical malfunctions : Any electrical issues or wiring problems should be addressed by a qualified technician to ensure safety and proper repairs. – Complex mechanical repairs : For complex mechanical repairs or component replacements, it’s best to entrust the task to an experienced professional who can effectively diagnose and resolve the issue.

Regular maintenance and prompt attention to issues can significantly prolong the life of your RV air conditioner and ensure reliable performance throughout your adventures.

However, if you encounter complex or persistent issues, don’t hesitate to seek the expertise of a professional for a thorough assessment and resolution.

Upgrade Options And Alternatives

Looking to upgrade your RV air conditioner window unit or explore alternative cooling options? From portable AC units to non-ducted applications, there are various options available to enhance your RV’s cooling system.

Let’s delve into the specifics of each alternative and compare them to traditional RV AC systems. Additionally, we’ll review the latest market additions, such as the innovative Noria unit, to help you make an informed decision for your RV’s cooling needs.

Exploring Portable Ac And Non-ducted Applications

When it comes to upgrading your RV air conditioning system, portable AC units and non-ducted applications offer convenient and versatile options. Portable AC units are especially beneficial for RV owners seeking flexibility and mobility.

These compact units can be easily moved from one location to another, providing cooling relief wherever you go. Additionally, non-ducted applications provide a viable alternative for efficiently cooling your RV without the need for complex ductwork installation.

Comparing Window Ac And Traditional Rv Ac Systems

When comparing window AC units to traditional RV AC systems, it’s essential to consider factors such as installation, efficiency, and cooling capacity.

While window AC units offer a simpler installation process and adequate cooling for smaller RVs, traditional RV AC systems are designed for optimal performance and durability in varying climate conditions.

Evaluating these factors can help you determine the most suitable option for your specific RV cooling requirements.

Reviewing Latest Market Additions Like The Noria Unit

The Noria unit stands out as one of the latest additions to the RV air conditioning market, offering innovative features and efficient cooling capabilities.

Whether you have a compact camper or a spacious motorhome, the Noria unit ensures reliable cooling and heating to keep you comfortable on your travels.

Its advanced design and performance make it a compelling option for RV owners seeking an upgraded cooling solution. Exploring the features and benefits of the Noria unit can provide valuable insights into the potential advantages of incorporating this cutting-edge technology into your RV.

Frequently Asked Questions On Rv Air Conditioner Window Unit

Can you put a window unit ac in an rv.

Yes, you can install a window AC unit in an RV for efficient cooling and heating, keeping you comfortable in various small spaces. It may require a customized solution.

Can I Put A Portable Ac In My Rv?

Yes, you can put a portable AC in your RV for efficient cooling and comfort. It may require a custom solution due to the RV’s design, but it’s possible for both compact campers and spacious motorhomes.

How Many Btus Does It Take To Cool An Rv?

It takes around 13,500 to 15,000 BTUs to cool an average-sized RV effectively.

Can You Leave An Rv Air Conditioner On All The Time?

Yes, you can leave an RV air conditioner on all the time as long as it’s connected to a power source like shore power or a generator.

Whether you have a compact camper or spacious motorhome, a window AC unit can provide efficient cooling and heating solutions to keep you comfortable during your travels. With the availability of various portable and affordable models, you can easily find the right fit for your RV’s cooling needs.

Additionally, with a reliable power source, running an RV air conditioner continuously is possible.

Related posts:

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

- Privacy Policy

RV Trips & Travel

Advise to Keep you and your RV in Good shape

Air Conditioner · January 20, 2022

Installing a Window AC Unit in an RV step by step

You might just need a bit more cooling in your RV. Whether you have an in-unit air conditioner in your RV or not, the heat of summer can still get to you. That’s probably why you are considering getting a window AC unit for your RV.

Mounting a window AC unit is a simple task for a do it yourself RV owner. You’ll need some tools and an instruction manual, but we can help you get this done.

Mountain a window AC on your RV involves some decisions including whether or not to make a frame. You may need to make a frame to hold your AC in place. You’ll also need to choose it’s placement based on the availability of power. Frame or not, screws or bolds are the next most important part ofmounting your AC unit to an RV.

Does it measure up – mounting a window AC unit in an RV.

You’ll first need to decide where to mount your window AC unit, then you can decide how to mount it.

Which parts of your RV get the warmest? Does this part of the RV also have a window or a place to open? Your AC unit needs both an outside air supply and electricity, so keep that in mind.

An RV AC unit needs a relatively large amount of electricity, measured in amps, to start up. Most RV AC units will need 16-18 amps to get kick started. This is about the same as a smaller air conditioning unit but less than a large one that can take 30 amps.

Inside of your RV breaker box, check the capacity of the breaker where you want to plug in your AC unit. RV breakers can come in a range from 10amps up to 30. Also, check to see what else is plugged in on the same circuit and how many amps that requires to run at the same time.

If you plug too much into one circuit and the air conditioner turns on, your circuit breaker might turn off the power to those outlets if it gets overwhelmed.

An RV AC unit needs a good frame to be useful – and not potentially fall and hurt somebody.

Your home is not much different from your RV for an air conditioner. The air conditioner needs a window frame to drag outside hot air in and cool it.

In the case of most RVs, you can readily attach an air conditioner to the rear of the RV and have it poke out of a window and add negligible length of your RV. This situation is ideal because it might not require modification.

If your heat problems are on the side of the RV, you might want to consider adding the AC unit there instead. The side can add width to your RV, which isn’t always ideal.

Making a frame

Consider consulting your RV’s manual to see which frames are meant to handle an AC unit. AC units are not light.

You might need to reinforce a frame with wood or plastic and screws to make it sturdy enough to hold an AC unit. This is often done by bracing wood pieces or 2 x 4 or smaller on the inside of a window so that the hole is the right side for an air conditioning unit while also having the weight capacity to not break.

Ideally, you can make the frame and air conditioner removable too. Build a top and bottom frame that keep the air conditioner from falling in by having wood pieces surround the fins on top of the AC unit. The AC unit itself will provide the pressure that keeps the bottom part of the frame in place.

The easiest way to do this is to measure the distance between the top of the window frame and the top fin. Just make sure it’s big enough to cover all gaps in the windows while offering a space to keep the top part of the unit from moving. You might need to make smaller, rounded cuts to the wood for this to work.

Much of the frame can be screwed or glued to the inside of the RV to avoid making big holes on the outside. You can also paint the frame so it looks uniform with the rest of the RV.

The window needs to be larger than the smallest size of the AC unit. Measure both the AC unit you want and the size of the frame and hole you have.

One fundamental issue you might come across is that the window in the area you want to cool is not big enough, or lacks a window at all. One potential solution is to create a hole for the purpose, though it might not be worth making a hole in one specific spot if you aren’t using the air conditioner often.

Will the mounting brackets that came with my AC unit work?

Honestly, probably not. These are moreso made for a home unit and are designed for an already built frame – and to keep from scratching both the home’s paint and the air conditioning unit itself.

Can making a mount effect resale value?

Done right, a well made made for an air conditioner can raise the resale value. The mount can be some work that someone else didn’t have to do, so a buyer might appreciate the presence of an already placed, nice looking mount.

Any safety considerations?

A couple of them.

A window unit air conditioner makes your RV a bit wider. Be careful when pulling into parking spaces – you may hae added some inches, or even a foot to the width of your RV.

A good power inverter and electrical management system can be quite helpful. You did some hard work getting the air conditioning unit installed, so don’t let a power surge or a lack of current wreck the motor in your air conditioner.

If you have any doubts about the safety of your mount, or you notice that it’s weakening – fix or or call a contractor and see if things can be done better. A falling AC unit is quite dangerous as units can be rather heavy.

Mounting an RV AC unit can be simple with the right tools and some measurements. Some RVs are just about designed to accept a rear installed unit while others might require some wood or plastic working to make them safe and reliable.

You’ll also want to check to make sure you are installing your AC unit in a place with an outlet and enough amperage to power the air conditioner unit.

We hope you stay cool this summer!

RV Tips in your Inbox!

We don’t spam! Read more in our privacy policy

Check your inbox or spam folder to confirm your subscription.

You’ll Also Love

Why my RV Refrigerator freezes everything and how to prevent it.

Copyright © 2024 RV Trips & Travel

How To Install a Window AC Unit in a Travel Trailer

Installing a window AC unit in a travel trailer can seem like a daunting task. However, with the right tools, understanding of the process, and a bit of patience, it can be done efficiently. This comprehensive guide will walk you through the process, provide tips for optimal performance, and help you troubleshoot common problems that might arise after installation.

To install a window AC unit in a travel trailer, first choose a suitable location that can support the weight of the AC unit. Measure the dimensions of your AC unit and mark the area on the trailer wall. Cut a hole in the wall according to the marked dimensions. Depending on the weight of your unit, install support brackets or a frame. Slide the AC unit into the hole, ensuring it’s aligned with the air intake and exhaust holes. Insulate around the unit, connect it to the trailer’s electrical system, and test its performance.

Choosing the Right AC Unit

Before diving into the installation process, it’s crucial to choose the right AC unit for your travel trailer. The size of the unit you need will depend on the size of your trailer. A general rule of thumb is needing 500 to 650 BTUs of AC per foot of RV. For example, for a typical 24-foot RV, a 15,000 BTU air conditioner is recommended. However, other factors such as the number of people in the RV, the insulation, and the climate of the location you’ll be traveling to should also be considered.

Essential Tools and Materials

To install a window AC unit in a travel trailer, you’ll need the following tools and materials: – Cordless Drill – Drill Bits – Level – Tape Measure – Screws – Foam Insulating Strip – Foam Weather Stripping – Mounting Support Bracket (if necessary)

Installation Process

Here’s a step-by-step guide to install a window AC unit in your travel trailer:

- Choose the location : Decide where you want to install the window AC unit in your travel trailer. The location should be able to support the weight of the AC unit and should have enough space for the unit to fit.

- Measure and mark : Measure the dimensions of your window AC unit and mark the area on the trailer wall where you’ll be cutting the hole for the unit.

- Cut the hole : Using a jigsaw or another appropriate cutting tool, carefully cut the hole in the trailer wall according to the marked dimensions.

- Install support brackets or frame : Depending on the weight of your window AC unit, you may need to build a frame or install support brackets.

- Insert the AC unit : Carefully slide the window AC unit into the hole you’ve cut, making sure it’s properly aligned with the air intake and exhaust holes.

- Insulate and seal : Insulate around the AC unit to prevent hot air from entering the trailer and to ensure a tight seal.

- Connect to power : Connect the window AC unit to your travel trailer’s electrical system.

- Test the unit : Turn on the AC unit and check its performance.

Safety Precautions

Safety should always be a priority when installing equipment. Some key safety measures to follow include reading the manual, wearing appropriate protective gear, following the steps outlined in the manual, observing general safety precautions, and checking for compatibility issues.

Maintenance Tips

Proper maintenance of your window AC unit is crucial for its optimal performance. Some maintenance tips include cleaning the air filter monthly, checking for insect/animal nests, cleaning the condenser coils once per season, inspecting cooling coils for frost or ice, and scheduling regular professional maintenance.

Troubleshooting Common Problems

Common problems that might arise after installation can include hardware failures, software errors, network problems, or user errors. To resolve these issues, you can check the installation guide, identify symptoms and causes, run Windows Update, unplug extra hardware, repair hard-drive errors, troubleshoot software installation issues, check for compatibility issues, and seek assistance.

In conclusion, installing a window AC unit in a travel trailer is not as difficult as it may seem. With the right tools, understanding of the process, and a bit of patience, you can enjoy a cool and comfortable travel trailer in no time.

Frequently Asked Questions

How do i choose the correct size drill bit for the installation.

The size of the drill bit you need will depend on the size of the screws you’re using for the installation. Usually, the size of the drill bit should be slightly smaller than the diameter of the screw.

How do I know if I need to install support brackets or frame for my AC unit?

If your AC unit is heavy or if the wall of your travel trailer is not strong enough to support the weight of the unit, you should install support brackets or a frame. Always refer to the manufacturer’s guidelines on this.

What type of power source do I need to connect my window AC unit to in my travel trailer?

Most window AC units are designed to run on standard household electricity (110-120 volts). If your travel trailer’s electrical system can provide this, you should be able to connect your AC unit directly. If not, you may need an adapter or a converter.

How often should I schedule professional maintenance for my window AC unit?

It’s generally recommended to schedule professional maintenance for your window AC unit once a year. However, if you’re using your AC unit extensively, you might need to schedule maintenance more frequently.

What should I do if my window AC unit is not cooling my travel trailer effectively?

If your window AC unit is not cooling your travel trailer effectively, it could be due to a number of reasons such as dirty air filters, low refrigerant levels, or a malfunctioning thermostat. It’s best to consult a professional in such cases.

Related Posts

How To Use Fels Naptha in a Washing Machine

Why Does AC Make Me Sneeze?

How To Tighten the Handle on a GE Refrigerator

How To Change Roomba Dust Bin

Who is the Manufacturer of Simplicity Vacuum Cleaners?

How To Reset the Water Filter on a Kenmore Refrigerator

About the author, stanley gilmore, leave a comment cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Stanley is an appliance repairman with 10 years of experience. He has seen it all when it comes to broken home appliances and decided to share his knowledge by writing for ApplianceTeacher.

How Soon Can You Use an Oven After Using Easy Off?

How To Fix the F3 Error Code on an LG Oven

How To Fix a Garbage Disposal That Shakes

How To Set Auto Mode in LG AC

Where Is the Charcoal Filter on a GE Microwave?

How To Disable the Child Lock on a Samsung Dishwasher

- Find a Location

Choosing An RV Air Conditioner Unit

The most popular, and for good reason, RV roof air conditioners don’t take up any space inside the RV. They are the most effective at distributing air, especially in a ducted system. These units provide the most efficient cooling and many can also deliver heat if you have a model with a heat pump or strip.

Although leading the charts in performance , they also lead the charts in power draw and replacement cost.

RV Window A/C Units

It wasn’t until the Coleman Lantern LT series that I really noticed the emergence of window or wall-mounted units inside RVs.

One issue with using an overhead unit on a small camper is the potential to freeze you out. Most manufacturers consider a small RV air conditioner to be 13,500 BTU, which is too much for a small RV, even on the lowest setting. With a smaller RV, you also likely have a more limited power supply, and window units draw about half as much power as an overhead unit, on average.

Portable RV Air Conditioner Units

The most likely use for a portable air conditioner in an RV is to supplement a roof or wall-mounted unit. Their downsides include reduced cooling capacity, added setup time, and reduced storage space. However, there are also positives, such as quiet operation and less strain on your wallet.

Portable air conditioners are also an option for RVs without an air conditioner or a temporary A/C replacement. The best part is that adding one does not require significant modifications, like cutting into the roof or walls.

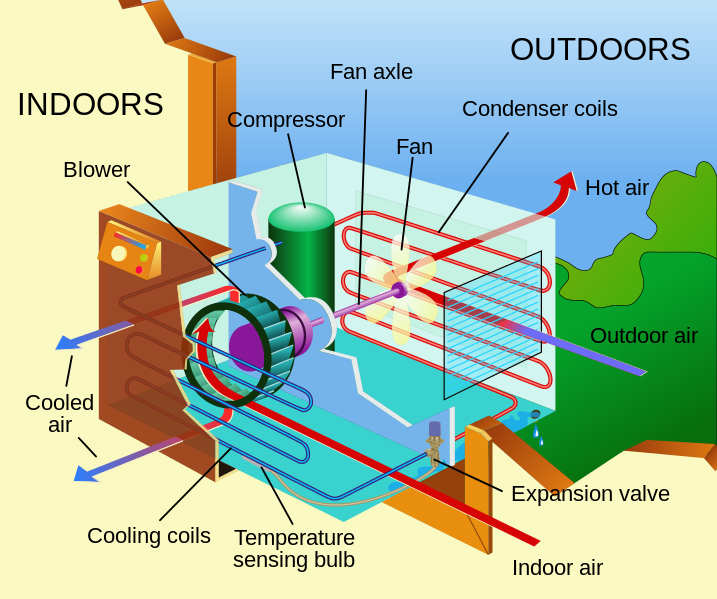

What Are the Different Rooftop Air Conditioner Components?

RV roof air conditioning systems are a collection of components that work together to deliver cool air throughout your camper. The main component is your roof-mounted unit, followed by the distribution box, a control module, and the thermostat. Some units come as a kit with all the needed items, whereas others require you to purchase them separately. Here’s how each component in the system functions:

The A/C Unit

The main component of an air conditioner for RV roofs is the unit itself. The unit contains all the internal air conditioning parts, such as the coils, condenser, compressor, etc.

Distribution Box

The distribution box is mounted inside the RV to the ceiling directly below the A/C unit. It distributes air throughout the RV through one or multiple vents.

Control Module

The control module is mounted to the distribution box or inside the unit. It controls all the settings, such as air speed and temperature. It is the system’s brain that communicates with the A/C unit, distribution box, and thermostat.

The thermostat tells the A/C unit when to turn on/off. It can be mounted on the wall (electric) or to the distribution box (manual).

The shroud protects the internal components of the A/C unit. Typically constructed of polypropylene, these covers are durable and weather-resistant.

The air filter is installed inside the distribution box in front of the vent. It blocks allergens, such as dust, pollen, mold spores, and more, from entering the RV.

Ducted versus Non-Ducted RV A/C Units

There are two types of roof-mounted A/C units: ducted and non-ducted. In a ducted system, ducts run through the RV’s floor, walls, or ceiling, and vents deliver the air throughout the floorplan.

A non-ducted system has only one vent at the distribution box. Air blows straight down from the unit into the RV. Non-ducted systems are standard for small RVs, while ducted systems are common in larger RVs with multiple rooms.

Distribution boxes are usually specific to ducted or non-ducted RVs, so you’ll need to know which type you have before selecting one.

How To Choose an RV Air Conditioner

The choice of an RV air conditioner can be overwhelming. There is an endless list of options and plenty of compatibility concerns. Let’s go over some common deciding factors to help you make a suitable choice.

There are two schools of thought behind choosing the right RV air conditioner brand. The first is choosing the same brand you have now to ensure compatibility. The second is choosing a different brand, with the expectation that you may have to replace multiple components to ensure everything works together. It’s a good idea to look at each brand and pick one that offers a system with the features you need. Some top RV air conditioner brands have been attached below for your convenience.

- Dometic (Brisk, Penguin, Blizzard, FreshJet)

- Coleman-Mach

Size (BTU Rating)

When most people talk about an RV air conditioner’s size, they’re referring to its BTU rating. British Thermal Units, also known as BTUs, are essentially a measure of power. The higher the BTU rating, the more cooling capacity the unit has. Most manufacturers offer a smaller 13,500 BTU RV air conditioner and a larger 15,000 BTU RV air conditioner. There are some oddball ratings as well, such as 11,000 BTU for smaller RVs.

Several factors, such as the size of the RV, insulation properties, and number of rooms, must be considered when choosing the correct size (AKA BTU rating) for your RV. We recommend sticking with the manufacturer’s suggestion, which you can get by calling the manufacturer directly with your vehicle identification number (VIN).

If your unit did not come with an air conditioner and you want to add one, you can use the general size chart below as an estimate.

Manual or Electric

A manual system is controlled via the distribution box, which means you must adjust settings directly on the ceiling unit. This may pose an issue if you’re shorter or have a high ceiling.

An electric system uses a wall-mounted thermostat for operation. Although most prefer a wall thermostat, manual systems are easier to install because you don’t have to run wires through the walls and ceiling.

There are many features to consider, but not all brands offer the same options. It’s important to select only what you need, as the more features a unit has, the more expensive it will be. A few examples of standard features are listed below:

- Heat Pump – Provides extra heat in colder months. Works best above 40 degrees Fahrenheit.

- Heat Strip – Designed to remove the chill, it should not be a primary heat source.

- Soft Start – Reduces start-up energy demands, allowing for a smaller generator.

- Condensate Pump – Channels condensation away from the roof and out a drain tube.

5 Best RV Air Conditioner Models to Consider

Are you feeling overwhelmed by all the A/C models out there? Our top five RV A/C units will help you get a reliable system to keep you cool this summer.

Dometic FreshJet 3 Series RV Air Conditioner

The most innovative rooftop air conditioner on the list is a Dometic RV air conditioner, the FreshJet 3. The FreshJet offers upgraded efficiency, quieter operation, and e-coated coils for added durability.

15,000 BTU Model Tested

Furrion Chill HE RV Roof Air Conditioner

The Furrion Chill is a highly efficient rooftop air conditioner with durable features like vibration protection and a thermal-insulated shroud.

15,500 BTU Model Tested

Coleman-Mach 15 Air Conditioner

One of the most tried-and-true RV rooftop A/C units on our list is the Coleman Mach. This high-performance air conditioner offers superior cooling and unrivaled durability.

Dometic Penguin II High-Capacity Air Conditioner

What’s unique about the Penguin is its low-profile design, which improves aerodynamics and helps cut down on fuel costs. Pair this with a high-performance motor for maximum cooling power, and you have an excellent rooftop option.

GE Exterior RV Air Conditioner

The GE air conditioner is cost-effective and reliable. It has rubber grommets to reduce vibrations, a glossy shroud to increase aesthetics, and easy-to-maintain coils for cleaning.

What Size Generator Do I Need for My Air Conditioner?

Generally, most 13,500 BTU RV air conditioners will require at least 3,500 starting watts, and 15,000 BTU RV air conditioners will need upwards of 4,000 starting watts.

When camping off-grid , there’s no access to shore power. Air conditioners draw too much power for your batteries, forcing you to use a generator . Unfortunately, generator sizing can be tricky. Due to space, weight, and fuel concerns, you’ll usually want to use a generator that is as small as possible.

Like generators, most air conditioners have running and starting wattage requirements. Starting watts represent how much power the unit requires on startup, and running watts represent how much power it needs to stay running. The starting watts can be almost double the running watts. You can reduce the power starting requirements with a soft start .

Learn more in this generator sizing guide .

Do I Need An Air Conditioner Cover?

If you don’t have an RV cover, a rooftop air conditioner cover is noteworthy for protecting the assembly when your RV is in storage. Use an air conditioner cover to keep dust, debris, moisture, and other potentially damaging substances from negatively impacting your air conditioner’s vital components.

Choosing an air conditioner is important, so we hope you found this guide helpful. Whether it’s a rooftop unit, wall mount, or portable system, keeping you and the family cool during warmer months is the ultimate goal.

Let us know what RV air conditioner unit you prefer or if you have any questions in the comments below.

Leave Your Comment Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

Shop By RV Type

Your Adventure Awaits

Copyright © 2023 cwi, llc all rights reserved.

- RV Glossary |

- Privacy Policy |

- California Privacy Rights |

- Do Not Sell or Share My Personal Information |

- Targeted Advertising Opt Out |

- Terms of Use

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

Our Gold Road

Vintage Trailer DIY & Family Camping

Installing a Window A/C in your trailer

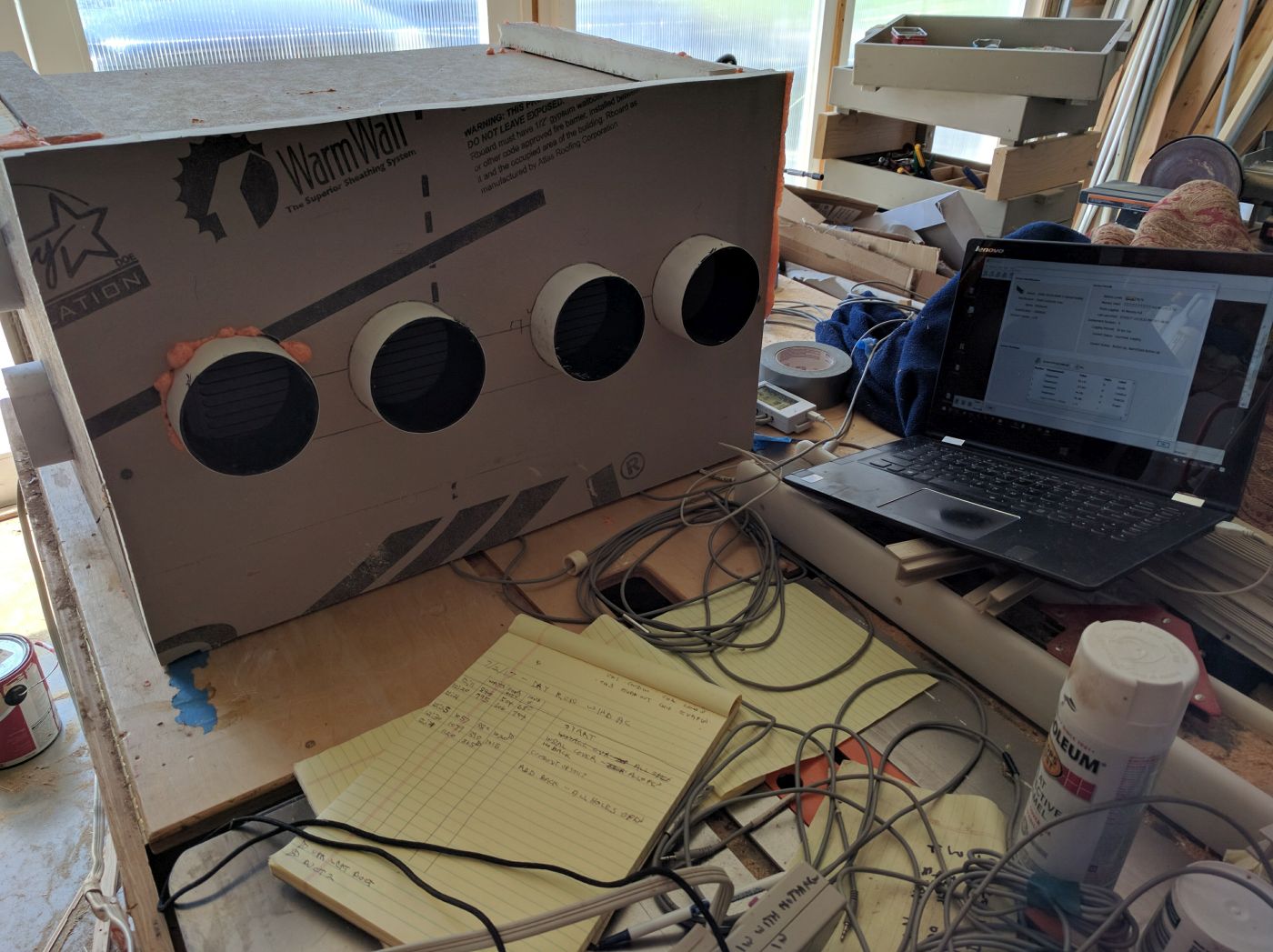

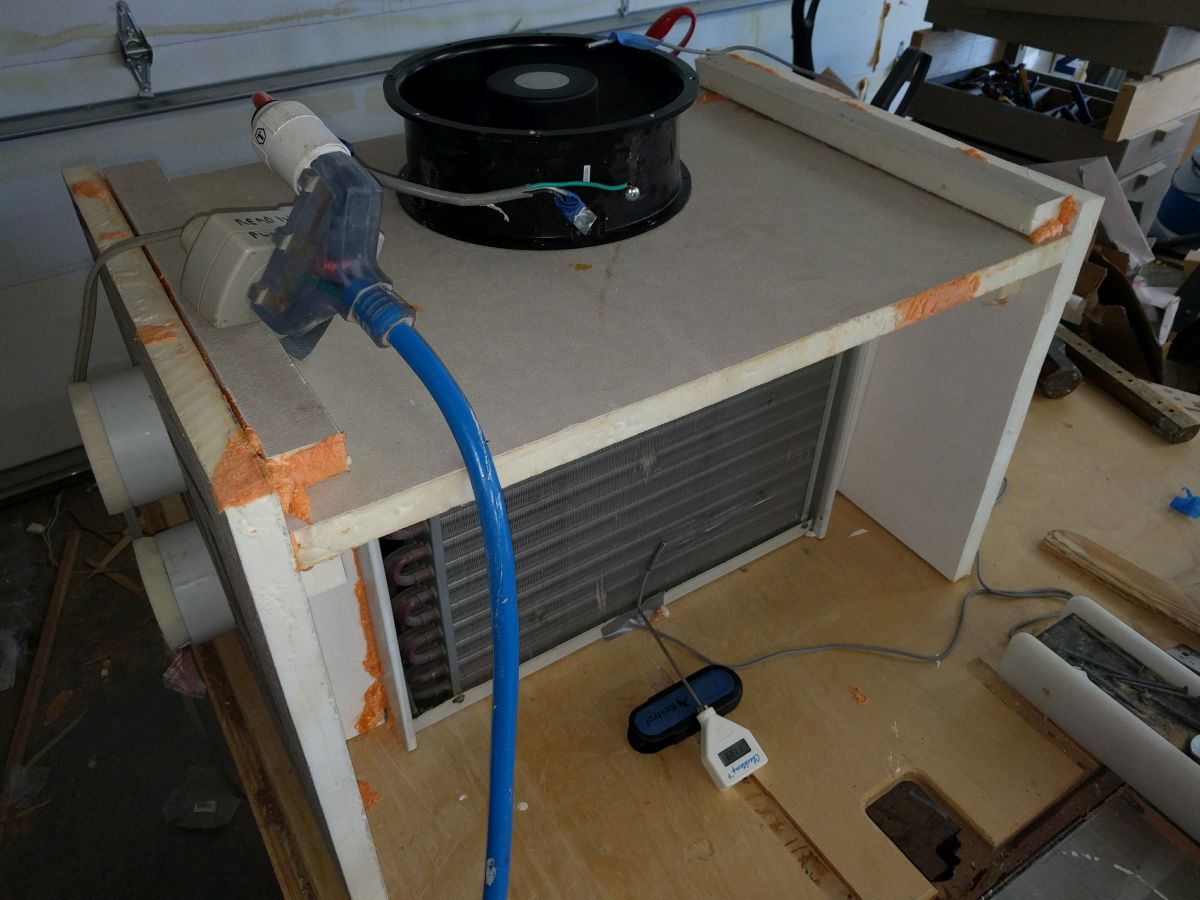

How to install an A/C on my trailer? A question we realized we must answer quickly after buying our first tiny trailer. We needed an A/C in our 1984 Uhaul CT-13 fiberglass trailer especially since we camp mostly in Texas. There were 2 options we had to choose from. We could have either installed a roof top air conditioner or figure out a way to use a window A/C in our trailer. We chose the latter.

The solution for you will depend on what type of trailer you own or plan to renovate. However, if you choose to install a window A/C unit as we did then let me give you some pointers. We want to give you an option that doesn’t include having an A/C sticking out the side of your beautiful trailer. Oh yeah…And of course there is a video down below to help you as well.

Things to remember when installing a window ac in your trailer.

1. Air intake

2. Hot air exhaust

3. Condensation

4. Electric

To assure your air conditioner works properly, you must remember to have a plan for outside air intake, heat exhaust as well as condensation.

First, you will need a hole cut on the side of the trailer (or we have seen some people install vents in the floor to pull air from underneath the trailer) so the A/C can pull in ambient air from outside. This air is blown through the condenser coils to cool them.

Second, you will need a hole cut directly behind the A/C unit to allow the heat from the coils to escape from the trailer. You need to make sure this hot air is not entering back into the trailer. We have seen some individuals insulate on top of the unit to keep this hot air from entering the trailer. However, we created a funnel system on the back of the A/C unit to force the air out through the hole we cut in our trailer.

Third, you will need to take into consideration the condensation that is created by the unit as it is cooling the air. Typically, the units are designed with the fan near the condensation pan to pull up the water and cause it to evaporate quicker, but this isn’t a perfect system, especially in hotter states. If your A/C doesn’t already come with some sort of condensation tube adaptor kit or attachment, then you will need to drill a hole in the condensation pan to allow the water to drain from the A/C unit. To assure this water exits the trailer completely, you will also need to drill a hole in the bottom of the trailer as well. Then you will need to attach a hose or create some sort of funnel system to guide the water out of the trailer. If you don’t create a system to catch the condensation then you will end up with water soaking the floor of your trailer.

Finally, and this will be short, let’s talk electric. I am not an electrician, so I did not come up with some fancy way to wire the A/C into the trailer. I just plug the unit into the outlet inside my trailer every time I need to use it. See…nothing fancy.

These are the most important things to remember if you plan to install an A/C inside your trailer. To see everything we did during installation be sure to watch the video below.

Reader Interactions

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

- Home & Kitchen

- Heating, Cooling & Air Quality

- Air Conditioners

Image Unavailable

- To view this video download Flash Player

FOGATTI RV Window Air Conditioner, 6500 BTU Cools up to 180Sq.ft, 4-in-1 AC Unit and Lower Noise, Suitable For RV and House-workshop, included Window Installation Kits (Matte Grey)

Delivery & support, about this item.

- Maximize Cooling: 6500 BTU Cooling capacity with up to 180 sq.ft RV space or same size room. Operates at noise levels as low as 50dB, providing a peaceful indoor environment for a comfortable rest and sleep experience during your camping journey. Incorporating R32 refrigerant, the air conditioner is environmentally friendly, efficient, reduces greenhouse gas emissions, and provides rapid cooling.

- Versatility Mode: The 4-in-1 mode window air conditioner integrates four functions, typically including cooling, fan, dehumidification, and Sleeping, to meet various seasonal and environmental needs.

- Simplified Mobility: Fogatti window air conditioner is lightweight and easy to carry, allowing for convenient movement to different locations in the caravan or for use in various indoor and outdoor settings. The window air conditioner is easy disassembly and installation with flexbility, therefore, it can be directly placed on the camper's window or other suitable positions without complex setup processes.

- Energy Saving: Window air conditioners are typically compact and lightweight, incorporating advanced cooling technology to enhance cooling efficienc. At the same time, they often use the envirinment standards R32 refrigerant, which is more efficient and requires less refrigerant compared to R410A. This allows them to achieve optimal cooling performance while being more energy-efficient, resulting in lower power consumption.

- Easy Installation: Fogatti RV window air conditioner is designed for simple installation on the windows of the RV, without the need for complex modifications. First, make sure you have the neceeary tools and additional installation accessories. Then find a suiable location for installinf the RV conditioner and install brackets and mounting devices in achosen location. Finally, test all the functions of the AC to ensure its cooling is working correctly.

- (PS: Due to version issues, there may be color differences) If you have any questions, please feel free to contact us.

Videos for similar products

Product information

Technical details, additional information, warranty & support, product guides and documents, what's in the box.

- RV Air Conditioner, Mounting Bracket*2, Accessory, Drain-pipe

Product Description

Compare with similar items

Looking for specific info, customer reviews.

Our goal is to make sure every review is trustworthy and useful. That's why we use both technology and human investigators to block fake reviews before customers ever see them. Learn more

We block Amazon accounts that violate our community guidelines. We also block sellers who buy reviews and take legal actions against parties who provide these reviews. Learn how to report

- Sort reviews by Top reviews Most recent Top reviews

Top reviews from the United States

There was a problem filtering reviews right now. please try again later..

- Amazon Newsletter

- About Amazon

- Accessibility

- Sustainability

- Press Center

- Investor Relations

- Amazon Devices

- Amazon Science

- Sell on Amazon

- Sell apps on Amazon

- Supply to Amazon

- Protect & Build Your Brand

- Become an Affiliate

- Become a Delivery Driver

- Start a Package Delivery Business

- Advertise Your Products

- Self-Publish with Us

- Become an Amazon Hub Partner

- › See More Ways to Make Money

- Amazon Visa

- Amazon Store Card

- Amazon Secured Card

- Amazon Business Card

- Shop with Points

- Credit Card Marketplace

- Reload Your Balance

- Amazon Currency Converter

- Your Account

- Your Orders

- Shipping Rates & Policies

- Amazon Prime

- Returns & Replacements

- Manage Your Content and Devices

- Recalls and Product Safety Alerts

- Conditions of Use

- Privacy Notice

- Consumer Health Data Privacy Disclosure

- Your Ads Privacy Choices

- Skip to main content

- Skip to secondary menu

- Skip to primary sidebar

- Skip to footer

Jeffsetter Travel

Travel Consultants and Travel Tips

8 Most Efficient Air Conditioners for Your RV

April 3, 2021 by Charlotte Phillips

Last updated on July 4th, 2023 at 04:50 pm

All of our reviews are based on exhaustive research, industry experience and whenever possible, hands-on testing. When you make a purchase using one of our chosen links we’ll receive a small percentage of the proceeds. This supports the site and keeps Jeffsetter running. You can read more here .

Looking for something to keep you cool as you travel the country in your RV this summer? I can’t blame you, especially if you’re heading into the desert or other equally hot places!

An air conditioner is one of the easiest and most successful things to use to beat the heat. But air conditioners are often inefficient and expensive, especially in an RV.

Are you looking for an energy-efficient air conditioner for your rig so that you can keep yourself and the whole family cool?

Let’s learn about your different RV AC options, as well as many other important things to consider before you make your final purchase! But if you want to skip the research and just see our favorites you can check them out here:

- Plug and play

- Redesigned with RVers in mind

- Lowest profile on the market

- Efficient cooling refrigerant

- Backed by a 2-year warranty

- Budget-friendly

- Lightweight and portable

- Easy to install

Types Of RV AC Units

The first step is determining what type of RV AC unit best works with your rig and lifestyle. Thankfully there aren’t too many different types to choose from, and the choice should be an easy one to make once you have determined your needs and wants!

Here are the three main types of RV AC units available for your consideration.

Rooftop AC Unit

Have you ever noticed large plastic covers atop the roof of newer RVs? These covers are most likely hiding a rooftop AC unit, the most common type of RV AC option. Most RVs, even back in the day, have the option to install an AC unit on the roof. Nowadays, AC units are standard atop the roof of your new rig, maybe even two (sometimes three, with a luxury fifth wheel )!

They can occasionally be a bit of a pricey nonstandard feature, but usually, it’s worth it to have AC aboard your rig. Rooftop AC units can be either ducted throughout the rig or non-ducted. This is an important distinction when it comes to your rig, and if you do not already have ducts installed you’ll want to stick with a non-ducted option for ease.

Ducts are usually what is found in standard homes with air conditioning. These ducts are installed throughout your RV, and the air is directed from the roof through these specified vents.

Most luxury RVs will have ducted ACs. Rooftop AC units can be just as useful non-ducted but tend to be a bit less efficient. This means the non-ducted unit simply blows cold air in from the ceiling. This can be perfect for smaller rigs like mine, or rigs with very few doors and walls.

However, much like the rest of the AC examples below, a ducted AC unit will no doubt be the most efficient and effective in cooling your home on wheels, especially if you own a larger rig with divided rooms.

Window AC Unit

My vintage rig does not have an air conditioner and, living full-time in the Pacific Northwest, this often does not trouble me. However, the summers can reach over 100 degrees sometimes, and this past summer I had no choice but to install a window AC unit in my RV.

Window AC units are meant to be permanent install in a window or cut out in your wall. The bulk of the unit sticks out of a window with filtration and a fan inside to keep you cool. Most units require or recommend support for the unit on the outside of the rig, which means it could be inconvenient if you are hitting the road often.

I’ve found these units to be quite heavy and unyielding in the past, a deep inconvenience if you have to remove them from your rig’s windows before driving. However, the price point is often quite reasonable, and new units are typically lightweight too.

Window AC units are also a bit trickier to fit correctly should you be installing one after your rig is built. However, there are a wide variety of sizes , efficiencies, and styles of window AC units. If you are doing a custom build where the unit can be permanently and safely installed or need something to work in a pinch, a window unit may be exactly what you need!

Portable AC Unit

Another option with a wide range of prices and styles is portable ACs. These can be useful, especially if you plan on removing them from your rig to use elsewhere in the future. Portable units are a bit misleading in their name, however, as even portable AC units need some sort of vent to the outside world.

The other style of portable AC unit is a swamp cooler, but these are not the same as air conditioners. While swamp coolers may work in a pinch, they simply use cold water and fans to work. This process puts a lot of moisture and humidity into the air and your rig, which can be a nightmare, as I’m sure you well know.

However, swamp coolers are very affordable and truly portable, often extremely compact. They would be a great fit for RV living if they didn’t produce so much humidity! So I recommend steering away from them and making sure you are looking at a proper AC unit, not a swamp cooler when shopping.

Portable AC units can do in a pinch , much like window units. They are movable so long as you keep a venting spot nearby, which means you may find this useful when it comes time to go to bed. You can bring the cool air with you! Well, so long as you can vent it out a bedroom window.

What To Look For In An RV AC Unit

If you’re still unsure what to look for in an RV AC unit, I can help. If the style of the unit didn’t narrow it down, here are some other factors to consider before you make your final purchase.

Existing AC Unit Location

Do you have an existing AC unit on your rig, but it’s time for a new one? The most natural choice for you to make is to simply replace your old unit and install the new unit in the same location.

However, if you don’t like your current style of AC unit, you may consider installing a different style or the same style in a more efficient location. This can bring a lot of headaches and hassle, so keep this in mind before you make a decision.

Obviously using the same location and style of AC unit will be the best bet for those of you simply replacing an outdated model. You may find the old location works just fine with a new, higher-efficiency unit installed there!

Are you a full-timer in Arizona, or the occasional weekend warrior to the balmy parts of our wonderful nation? Your predicted usage of your AC unit may be something to consider before making a final purchase.

Much like everything else in your RV, the amount of use it sees greatly affects the efficiency of the product or device. Purchasing an efficient and expensive AC unit may be worth it for you if you plan to visit hot places often, or live full-time in your rig.

However, if you deem an air conditioner necessary but only plan on using it a few times a year, chances are you can go with a cheaper model and notice no real issues.

Space, Space, Space

I’m sure you’ve no doubt realized, when it comes to storage and general living, space inside an RV is always at a premium. The last thing you want to do when purchasing an air conditioner is to buy one that takes up too much space in your rig.

A roof AC unit is usually the style of unit that’s most out of the way, but you have to consider the rooftop clearance of your rig before installing. Window units are the next most streamlined choice, but even these units can jut out pretty far into a particular space.

Portable units will be the most in the way (and also not completely portable), so these will be the unit you may struggle with the most. Keep your desired measurements handy when you sit down to make your final purchase!

BTU Requirements

A BTU, or British Thermal Unit, is how all air conditioners are measured. More BTUs equals more power, more cooling, and more everything! However, more BTUs also means more money, more often than not.

Determining your BTU needs can determine the AC unit you need to efficiently cool your RV. But how can you calculate something like that? Check out this formula and consider if your RV might be better suited with one or two AC units.

BTU Calculation:

Cubic Feet x Temperature Increase or Decrease in Fahrenheit x .133

Cubic Feet x Temperature Increase or Decrease in Celsius x .2394

Walls and doors should be taken into consideration when calculating your BTU needs. This is why a lot of larger fifth wheels these days have more than one air conditioner- the cold air struggles to pass by walls and doors to cool efficiently .

For maximum efficiency, knowing your desired BTUs will help, and if your BTU number is quite high based on the cubic feet of your rig, another air conditioner may be the answer.

Installing Your RV AC Unit

Installing your new RV AC unit may be a bit of an involved process, depending on your final choice and whether or not you want a professional to help you. If you plan on doing the installation yourself, it’s definitely possible!

Make sure you utilize your AC unit’s manual and follow all suggestions. The last thing you want to do is void a warranty, should your unit come with one. If you are installing a new rooftop AC unit, it’s recommended to have another hand around for your own safety.

These units, no matter how new, can be heavy and unyielding at the best of times. Lugging one up a ladder by yourself can be a lot! Take your time, be safe, and make sure you have all the necessary tools and equipment before getting started, such as one of these foldable ladders if you don’t already have one!

Maintenance And Tips For Your RV AC

Your RV AC unit can last many years, often for the life of your RV should you perform proper and routine maintenance. Much like most other parts of your RV, maintenance is the best way to ensure a long life for your rig.

AC units are usually fairly low maintenance, needing only filter changes from time to time which is an extremely easy thing to do. The only other thing you may have to do is recharge the liquid freezing system but refer to your manual before doing anything too extreme.

Having a cover for your unit is usually necessary too, should it not come with one already. Your rooftop AC unit absolutely needs one to protect it from the elements, and some window units may also benefit from a cover.

Otherwise, keep the vents dust free and pay attention to your unit’s efficiency as the months go by. High-efficiency AC units often need less maintenance and, while they can come at a higher price tag, they may be worth purchasing should you be wary of routine maintenance.

What About My Amperage?

If using your air conditioner is a high priority while on the road, you must consider your overall wattage and amperage . Most new rigs have 50-amp power systems, which is usually enough for AC units.

However, your air conditioner needs the most wattage out of all other appliances, including electric heaters or microwaves. Make sure you know how many watts your AC unit uses upon start-up. An air conditioner’s running wattage is always lower than its start-up wattage. Your electrical system will need to be able to compensate for the start-up wattage!

If your 50 amp rig includes two AC units (as many often do) and you hope to power them both at the same time, you’re going to need to make some sacrifices in terms of other appliances. You won’t be able to run everything at the same time.

Keep in mind your needs versus your wants. It’s a nice idea to want to power your entire rig and all major appliances at the same time, but your rig may not be able to handle it! Wouldn’t you choose a nice cooled rig instead of using a hair dryer?

8 Most Efficient AC Units For Your RV

Have you determined the best style of AC unit for your RV? What about your required BTUs and usage needs? If you’re ready, so am I! Here’s my list of the most efficient air conditioners perfect for your RV!

Best Overall: Dometic Brisk II Rooftop Air Conditioner, 15,000 BTU

Dometic brisk ii rooftop air conditioner, 15,000 btu.

It’s a perfect fit for replacing an old AC unit, and Dometic has been one of the biggest names in the RV game since the beginning, so I trust their handiwork! The Brisk Air II uses its smart design, tighter specification allowances, and improved materials to maximize airflow and performance so keeping cool in summer is easy. This RV AC unit offers a 15% airflow increase and is 19% lighter than previous models, which means direct improvements when replacing an older version.

This particular model works ducted or not ducted, but frustratingly, there is a need to purchase additional accessories for ducted options. However, having both ducted and non-ducted options provides me with the flexibility I need while I’m living on the road. It’s lightweight compared to many other units but weighs around 85 pounds, so I think I’d need my partner to give me a hand with the installation.

This is a considerable amount of weight to add to the RV roof, so I recommend proceeding with caution when installing it on the roof! However, it should have no trouble fitting any old AC spots; just make sure you know how much weight your roof can support .

All in all, this is one of the best AC units out there for RVs- powerful, reliable, and backed by a two-year warranty from Dometic which I love as there’s someone to call if things get hairy!

You can find out more about this unit along with the latest price on Amazon by clicking here.

Lowest Profile: Dometic 640315CXX1J0 Penguin II

Dometic 640315cxx1j0 penguin ii.

This model of Penguin AC comes in at around 100 pounds and runs at 13,500 BTUs. This is a relatively heavy weight for installation which I think is the main drawback of this AC unit. However, I just recruit some family, friends, or my partner to give me a hand when heavy additions to my RV! This Dometic Penguin also only rises to 9 and a half inches tall, which means I feel secure going under any overpass in my rig – low branches won’t snag this AC unit either!

This particular model is meant for non-ducted rigs, so this is something to keep an eye on for those preferring a ducted option. However, much like other Dometic AC units, it’s a fairly simple plug-and-play appliance so once it’s in place, the rest of the installation should be relatively straightforward.

It also utilizes energy-efficient refrigerant, perfect for me since I have an eye for efficient cooling! I’m a little nervous about heights, and always prioritize safety first, so make sure you’re careful getting this unit up to the roof!

Check out the latest price on Amazon by clicking here.

Best on a Budget: COSTWAY 12000 BTU Portable Air Conditioner with Remote Control

Costway 12000 btu portable air conditioner.

This 12,000 BTU model efficiently manages the ambient temperature of spaces up to 400 sq/ft, removing heat and humidity for seasonal or year-round comfort which as a full-timer, is exactly what I need! Designed with cooling mode, dehumidifying mode, fan mode, and sleep mode, this conditioner meets various demands, especially in small spaces such as my travel trailer.

I love the convenience having a remote control brings, as I can operate the air conditioning unit from a long distance, so my partner, dog, and I can return to a gorgeously cool rig after a long summer hike. The included slide-out filter is super easy to clean too, I just have to rinse it under the faucet and I’m rewarded with fresh, cool air! A window kit is included for easy installation, and all it needs is a sliver of access to the outside world.

This portable air conditioner has two drain ports – an upper drain port and a lower drain port. And you can choose between manual drainage and continuous drainage, which may be useful to some of you. It measures 12 x 29 x 13.5 inches and weighs around 50 pounds. Plus it has attached wheels, which means you’ll be able to move it with ease.

The only issue I can see with this AC unit is that it may not be the best fit in an RV given that it does take up a considerable amount of space. However, if you don’t have an existing rooftop AC unit and want something that is incredibly efficient and easy to install, this may be a great unit for you.

You can see the latest price and reviews on Amazon by clicking here .

Best Rooftop AC: Dometic Air Conditioners 651816CXX1J0 Penguin II

Dometic Air Conditioners 651816CXX1J0 Penguin II

- Heats and cools

- Great warranty and customer service

From 60°F to 38°F, this Penguin II heat pump can keep RV interiors comfortably warm, as well as cool. Space is luxury in an RV, so I tend to lean more towards items that do more than one job, as it saves space, money, and time in the long run! This unit operates entirely on 120-volt AC electricity, so there’s nothing to light and no LP gas supply to worry about which I love as it makes things even easier.

It’s also less than 10 inches tall! It’s incredibly easy to install when replacing an old AC unit, and is, therefore, more efficient in every way. Plus it works with ducted and non-ducted RVs. As previously mentioned, Dometic offers great customer service and two-year warranties which proves Dometic trust their products, and I do too! There’s no denying this is a fantastic rooftop AC option, however, there are a few downsides in my eyes.

Firstly, it weighs over 100 pounds which is a substantial amount of weight to handle, especially for solo RVers. It also requires a specific thermostat which is sold separately, which as a result bumps the overall cost up a considerable amount. All in all, though, this AC unit is the best of the best in terms of rooftop options. It’s great to have an all-in-one, and may come in handy should your propane or other heater fail.

You can see the latest price on Amazon by clicking here .

Best Window AC: Midea MAW10R1BWT Window Conditioner 10000 BTU Easycool AC

Midea MAW10R1BWT Window Conditioner 10000 BTU Easycool AC

- Remote controlled

This 10,000 BTU model provides fast and efficient cooling power and dehumidification, ideal for rooms up to 450 square feet. An intuitive design remote control and a LED digital display panel make it easy to change all the settings from across the room. I love this type of convenience as it makes things super easy for both my partner and me. This window unit installs easily without significant modification to the existing window frame, and all mounting hardware is included which is a game-changer, as nothing frustrates me more than additional purchases for a product!

This unit is recommended for specific-sized windows: minimum window height- 14 inches, minimum window width- 23 inches, maximum window width- 36 inches. I think this is the only tricky part when it comes to installing this AC in a rig, as most RVs aren’t designed to hold a window or wall AC unit.

Thankfully this AC only weighs around 60 pounds, much lighter than the rooftop models I previously mentioned, so solo installation is completely possible! I particularly love that it cools the air quickly. which is what we need with a dog on board , but also runs quietly so it doesn’t interfere with RV living.

Check out the latest reviews and more on Amazon by clicking here .

Best Portable AC: BLACK+DECKER Portable Air Conditioner, 12,000 BTU with Heat

BLACK+DECKER Portable Air Conditioner, 12,000 BTU with Heat

- Cools and heats

- Low amp and efficient

- Compact and easy to use

- Installation included

It can sometimes be a bit of a hassle to find a two-in-one RV AC option, but fear not, as I’ve found a BLACK+DECKER Portable AC that’s a winner. A household name for many appliances and accessories, Black and Decker have put together a portable AC unit that also heats! This appliance is a powerful, portable, and energy-efficient option for when a permanent AC installation isn’t suitable.

An adjustable fan speed cools the air up to 55°F, heats up to 81°F, and provides steady and fast cooling and heating for rooms up to 250 sq. ft. This is ideal for my travel trailer, and the fact it has dual functions means I can save money by not using my propane heater ! The simple remote control and top-mounted LED display with a 24-hour timer allow me to precisely control the air temperature. To clean the filter, I just slide it out twice a month, rinse it thoroughly under running water, and put it back.

Combining 4 energy-efficient modes in one small unit (17.1 x 13.8 x 28.1 in.), the cool, fan, heat, and dehumidify settings meet all of my RV’s cooling, heating, and ventilation needs. There are additional settings too, namely sleep, max, and air swing functions that control airflow, all whilst only drawing 10-12 amps.

Weighing around 60 pounds, it’s not too heavy, but it does take up a considerable amount of space which may not be ideal for small RVs. However, if you’re looking for a semi-compact unit able to both cool and heat your rig, whilst also having an included warranty from Black and Decker, it may just be worth it.

See more from this RV AC unit and read the latest reviews on Amazon by clicking here .

Most Versatile Option: Zero Breeze Mark 2 Battery Powered Portable Air Conditioner

Zero Breeze Mark 2 Battery Powered Portable Air Conditioner

- Versatile charging options

- Lightweight

I like versatility in my rig, which means I expect a lot from the RV products I purchase! I’ve already talked about a BLACK+DECKER portable AC unit, but I’ve found an impressive unit from a lesser-known brand that really packs a punch. This Zero Breeze Mark 2 Battery Powered AC is compact, measuring just 0.9″D x 8.3″W x 1.6″H, and is ideal for when I head out on the road alone as I can move it around to exactly where I need it to be.

I enjoy using the useful handle as it makes maneuvering the device around convenient and easy. Since it only weighs 16.5 lbs it also doesn’t add a substantial amount of weight to my RV which is ideal as it’s pretty loaded already! This little unit doesn’t skip a beat with function and ability as it has a strong compressor, 24V operating voltage, high-performance battery system, and has the capability to be powered by 4 x 100W solar panels which is the perfect option for off-grid camping and boondocking .

Some RV AC devices I’ve seen require the use of ice or water, but this little device doesn’t need either, and as soon as it’s plugged in, the air gets cooler in such a short space of time. I like the use of a Smart Battery as it only takes 5-8 hours to be fully charged. This may be too long for some, but I think it’s a small price to pay for such a cool (pardon the pun!) and functional little unit.

The remote control makes using this Zero Breeze unit a breeze, and included with the AC device is a 24V power adapter, battery, dual-duct exhaust system, front air duct, drainage tube, and a user’s manual.

Check out the latest reviews and prices on Amazon by clicking here .

Quietest Rooftop AC: Furrion CHILL Rooftop Air Conditioner with Electric Control

Furrion CHILL Rooftop Air Conditioner with Electric Control

- Enhanced safety features

- 2-year warranty

I travel year-round in my RV and I love nothing more than returning to my rig in the height of summer, switching the AC on, and cooling right down! Some RV AC units get the job done, but make an absolute racket during the process!

Well, not with this super-quiet Furrion CHILL Rooftop AC! It fits on the roof, has 15,500 BTUs, and includes an air distribution box, and a single basic wall thermostat so there’s not much else required to get this bad boy up and running, as discussed in the video below:

Although this unit runs quietly, it still cools in an energy-efficient way, thanks to the addition of two fans with individual motors to get the air inside an RV cooled fast! I’ve mentioned before how much I value safety and I think it’s awesome Furrion has taken things to the next level with the safety of this AC. There’s a start capacitor to aid the initial start-up of the device if the power in an RV is a little on the low side and short-cycle protection too.

I find I’m always trying to protect my RV from the sun , but Furrion is ahead of the game as they’ve created a UV-resistant cover to protect internal components. There’s also thermal insulation to aid in heat regulation so the device doesn’t overheat, even when the sun is beaming down and it’s scorching outside.

The running of this AC is quiet as I mentioned earlier, but the rubber dampeners also help make things more peaceful as they help prevent vibration! It’s features like this that prove to me Furrion has designed a product with RVers in mind, which I think makes all the difference.

For extra security, there’s a 2-year warranty, so I can keep cool and comfortable knowing my device is covered by Furrion.

Find out more and see the latest price on Amazon by clicking here .

Finding an efficient air conditioner for your RV is easier than ever before. While rooftop AC units are traditionally useful, keep in mind all of your options before making a final purchase. No matter what, it’ll be easy to keep cool this summer with one of these units!

Important Links

- Advertising Policy and Affiliate Disclaimer

- Privacy Policy

- Contact Jeffsetter Travel Blog

- Ask Jeffsetter a Question

Recent Posts

- Trip Report: Visiting Maui Post-Fire

- Hilton Honors Surpass 2024 Review

- Oneworld is Getting New Members

- Tragic Drowning Reignites Tourism Debate

- Alaska Air Will Offer Surprise Upgrades

Guiding Adventurous Souls Through RV Life

How to Install a Window Air Conditioner in a Pop Up Camper

Share with a friend

Last Updated on March 14, 2023 by Jessica Lauren Vine

Do you wonder how to install a window air conditioner in a pop up camper?

One of the most important aspects of enjoying a weekend of camping is having an air conditioner. A pop up camper will quickly become a hot box if you try to spend any amount of time without an air conditioner. However, because of how pop up campers work, they can’t have a permanent air conditioner installed on them.

To thoroughly enjoy your pop up camper, you should learn how to install a window air conditioner in a pop up camper. Window air conditioners can easily be installed and removed each time you set up and break down your camper.

In this article, we’re going to take a look at how to install a window air conditioner in your pop up camper, as well as how to remove it. We’ll also look at the best types of window air conditioners and what you can do to help yours last as long as possible. Let’s dive in!

Table of Contents

Is a Window AC the Best Option for a Pop Up Camper?

A window air conditioner for your pop up camper isn’t just one of the best options. It’s one of the only options. Outside of a window AC, you really only have two other options: a portable air conditioner or a rooftop unit.

Portable air conditioners are the easiest air conditioners to install, and they operate similarly to a dehumidifier. You can have it sitting anywhere inside your camper, and all you need to do to operate it is plug it in and turn it on. Most portable air conditioners also have a flexible hose coming out of the back that needs to be vented to the outside.

A roof-top air conditioner is another popular option for campers of every sort, but they don’t usually come installed on pop up campers. Installing one yourself is hard work, and rooftop air conditioners are much pricier than window air conditioners.

That brings us back to window air conditioners. They are the cheapest option and require basically the same amount of work that a rooftop air conditioner requires. Let’s take a look at how to install one if that’s the route you decide to go.

How to Install a Window Air Conditioner in a Pop Up Camper

Let’s take a look at how to install your window air conditioner in your pop up camper. In order to complete this project, you’re going to need some tools.

Tools You’ll Need to Put a Window Air Condition in a Pop Up Camper

- Utility knife or another sharp work knife

- Tape Measurer

- Saw to cut wood

- Drill

- Screws

- Drill bit

Choose Your Air Conditioner

In order to begin your project, you first need to choose the right air conditioner for your camper. Pop up campers are notoriously small so you won’t need a large air conditioner. In fact, many people either purchase the cheapest or smallest window AC that they can get their hands on. Other people keep their eyes open for a used or free one and take anything they can find.

In general, most any window air conditioner is going to be big enough to cool down your camper. Smaller air conditioners are actually a better option for your camper because you’ll have to build a bracket to support it.

Choose Your Location

After you have your air conditioner and you’re into how to install a window air conditioner in a pop up camper, you’ll have to pick where you want it. Your options when it comes to the location are fairly open. Some people like to have their air conditioner in the solid part of the camper, while others prefer the fabric tent portion. Another aspect that people look at is whether they want it high up or down low.