Whipstock Systems

Graco’s MasterTech redefines the cased wellbore exit landscape with its cutting-edge, single trip whipstock system.

Graco MasterTech redefines the cased wellbore exit landscape with its cutting-edge, single-trip whipstock system. This isn’t just a solution; it’s a dynamic whipstock system meticulously crafted to set new industry benchmarks.

With its cost-effective approach for exiting cased wellbores, Graco’s MasterTech’s compact design, short whipstock length, and compact milling assembly enable the creation of a shorter window-exit Bottom Hole Assembly (BHA).

This system brings seamless navigation through the most severe doglegs. Experience a quicker kickoff and achieve a higher build rate in short-radius applications, all while ensuring retrievability for multi-zone operations.

Elevate your drilling operations with MasterTech, the ultimate retrievable whipstock system engineered for excellence.

Continued Excellence. Year After Year.

Customers turn to Graco for our distinct expertise and service, driven by our understanding of the costs tied to operational halts and potential asset loss.

Get in touch with a member of our team; we’re ready to support our customers 24/7.

Learn More

Explore the future of single trip whipstock systems with our MasterTECH Whipstock flyer – your gateway to unmatched innovation, efficiency, and reliability.

MasterTech Whipstock Flyer

For personalized assistance or inquiries, reach out to our team of experts

Directional Drilling Services

John M. Phillips Directional Drilling Services combine quality drilling equipment, premium software, and experienced drillers to provide a full range of drilling solutions that are safe, reliable, and cost effective. Our team has successfully drilled in a wide variety of environments including oil, gas, mining and geothermal.

FISHING SERVICES

John M. Phillips Fishing Services provides a full line of cased-hole, open-hole and thru-tubing downhole fishing tools that are expertly applied at the well site by knowledgeable fishing tool supervisors that are among the best in the business. Fishing Services’ personnel have more than 20 years of advanced fishing experience, ensuring customers will receive the best tools, equipment, and service in the industry.

WhipStock Services

John M. Phillips Single Trip WhipStock Service is available for casing exits up to 16-inch OD casing and may be ordered with mechanical or hydraulic set option. This WhipStock service features integral blade mills with advanced carbide inserts designed to exit single or dual string programs in one trip and may be retrieved if necessary

Survey Services

John M. Phillips Directional Survey Services provides the latest innovations in gyro surveying technology. We provide services for Oil and Gas, Mining, Geotechnical, Geothermal and Civil Engineering. Success in these highly competitive drilling markets depends on always moving in the right direction . Drilling operations have countless constantly moving parts, making unbroken efficiency a priority for every team. Incorporating new technology is not just a benefit – it is a necessity

Workover and ThruTubing Services

John M. Phillips Workover Services team solves customer challenges ranging from routine to highly complex. Our Workover service package includes a full line of thru-tubing tools, fishing tool, milling tools, pumps, mud tanks, power swivels, casing, and tubing handling accessories and more.

Underreaming Services

John M. Phillips Underreaming Services provides a full line of Underreaming tools for borehole enlargement. JMP uses field tested and proven fixed cutter and retractable arm tools that are fitted with TCI or milled tooth cutters depending on formation composition. JMP provides Tool body sizes ranging from 4-3/4 OD capable of enlargement to 9-1/2 inches and a 22” OD body to enlarge wellbore to 40”

Technology and equipment for window-cutting in cased and/or open hole well by application of one-trip whipstock with hydraulic anchor/packer

- One trip whipstock

- Our whipstock, although very simple in design, provide a reliable anchor.

- The use of our whipstocks allows the cutting of the window in casings without any cementing or similar operations with inclinations up to 90º.

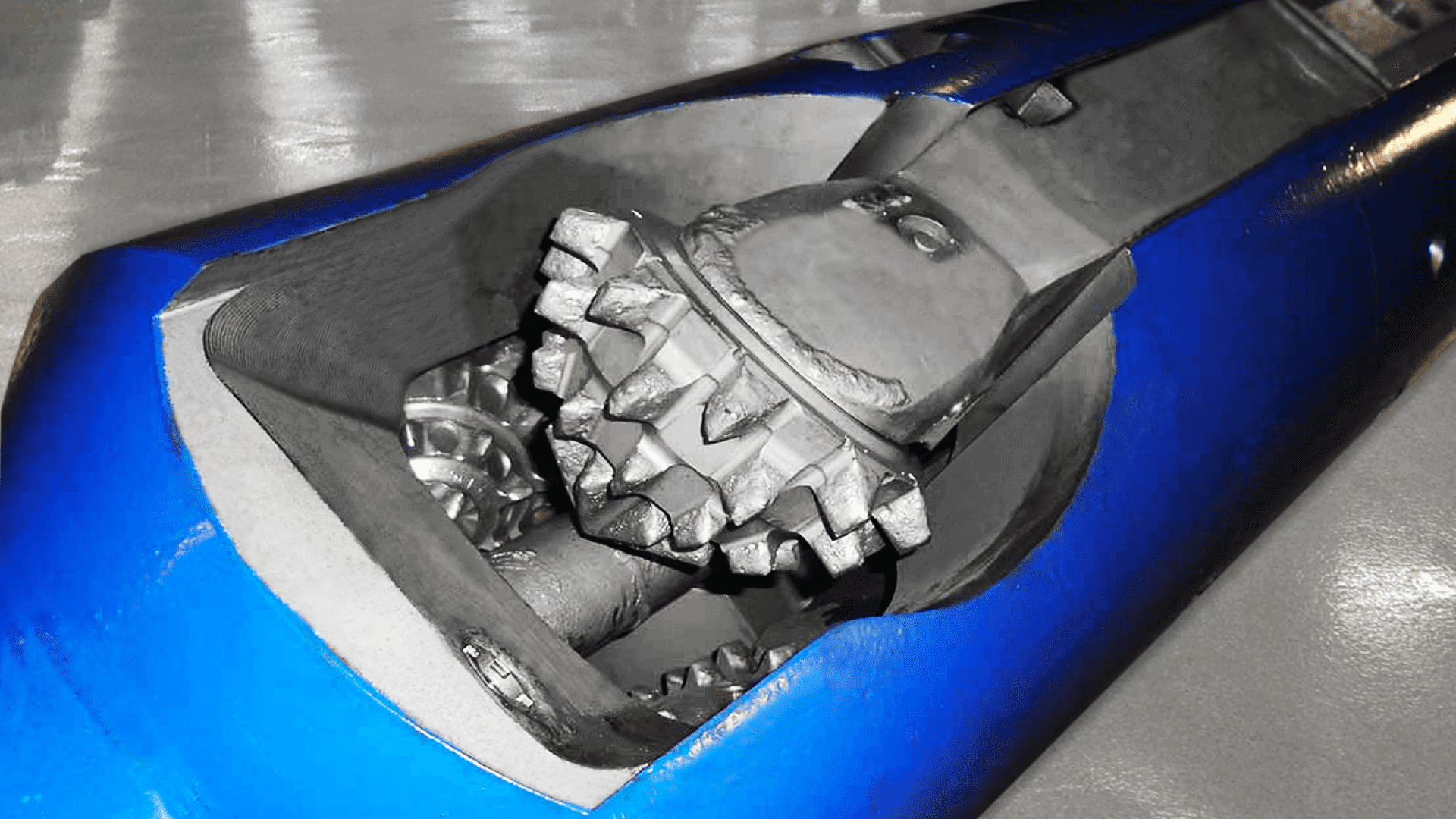

- The double mill cutter is reinforced with metal-ceramic composition and reinforced by alloy plates that make possible high-speed milling.

- The use of our whipstocks makes possible window-cutting operations of only 4 to 8 hours, depending on casing thickness, casing steel grade, and inclination angle in the window-cutting interval.

- Whipstock system can be used with Close Valve System (CVS) for orientation by MWD. CVS allows to circulate while running at any depth with flow rate up to 600 GPM.

- Topics Onshore Exploration Drilling Completion Production Shale Hydraulic Fracturing Conventional Digital Transformation Automation & Control Data Storage Artificial Intelligence Offshore Exploration Drilling Production Deepwater Subsea Decommissioning Energy Transition LNG Sustainability Offshore Wind Hydrogen Carbon Capture Industry & Analysis Economics/statistics Regulatory ESG/Investment Regions North America South America Europe Eastern Mediterranean Russia & FSU Africa Middle East Far East South Asia South Pacific Arctic East Asia Australasia

- Magazine Current Issue Archive Free Trial Subscription Full Access Subscription Renew Subscription Supplements Forecast Reprints & Back Issues

- News Latest News Company News Newsletter Sign-Up

- Resources Webcasts Whitepapers eBooks Podcasts Videos Upstream365 Event Presentations Maps Store

- Events World Oil Events Gulf Energy Information Excellence Awards Women's Global Leadership Conference Deepwater Executive Summit Oilfield Electrification Technology Conference World Oil Forecast MCE Deepwater Development

- Project Data Global Energy Infrastructure

- Manage Account

- North America

- U.S. Onshore

Weatherford installs 113 consecutive whipstocks with 100% single-trip execution

HOUSTON - Weatherford International announced a milestone of 113 consecutive cased hole whipstock jobs completed in a single trip. The installation success began with the first run in February 2018 and reached number 113 in October 2019. Weatherford accomplished this notable success exclusively in California, with zero nonproductive time.

Flawless execution. “This is an industry-first achievement,” said Dean Bell, president of Well Construction for Weatherford. “Our work in California involved six operators and exits from seven casing sizes. Weatherford crews logged a remarkable 3,577.5 working hours with an average mill time of 2.88 hr/run. There’s no doubt this unprecedented success was made possible by absolute operational adherence to process and procedures at every level, from the shop to the field.”

Decades of system development. A critical component of the whipstock installation success in California was Weatherford’s QuickCut casing-exit system, Fig. 1. Designed specifically to meet a variety of customer requirements, the system improves milling performance and penetration rate, as well as maintains gauge retention of the milling assembly. Coupled with the industry’s most competent people, QuickCut reduces rig time, achieves the objective in one-trip, and exceeds the performance of alternative systems.

The QuickCut system enables operators to design an exit that exactly meets their well-specific conditions, whether plans necessitate short radius, extended reach drilling, or challenging completions installations. The system gives operators the ability to create a smooth transition from the parent wellbore into the lateral section.

The QuickCut casing-exit system can be applied to sidetrack and exiting through multiple casing strings, wellbore restrictions, and wells with high- and low-side exits. It can also be used to access bypassed or behind-pipe reserves and in horizontal and multilateral installations or wells with high-dogleg severity. The system offers the following technological advantages:

- Mechanical or hydraulic actuation enables complete well control while circulating, logging, or drilling. Hydraulic actuation removes the need for a false bottom to prevent costly bridge plug installations.

- Exit any casing size or weight.

- One size anchor catches multiple sizes and facilitates passage through restrictions.

- Lead-mill technology provides full-gauge windows and ratholes with single-trip efficiency to reduce rig time and costs.

- Lug technology protects the whipstock during cutout and accurately directs the lead mill into the casing wall.

- Casing exits can be created independently of the hole inclination, which makes high- and low-side exits possible up through 9 5/8-in. casing.

Employee development. Weatherford’s learning and development programs are critical to the continued success of the different global product lines. These programs consist of soft-skills and technical training, a comprehensive competence assurance program and structured career paths:

“The Intervention Services (fishing and re-entry) training curriculum includes online computer-based training, classroom, and hands-on training, focusing primarily on the use of the operational control plan, technical work instructions (TWI), checklists and forms. It also includes soft-skill development of our field population,” according to Weatherford’s V.P. of Intervention Services, Chris Cutrer.

Weatherford’s Competence Assurance Program is a risk-based competence assessment process that assures our personnel have the capability to deliver our services as per operating standards. Following this methodology, the assessment program is structured in three components:

- Weatherford Core – minimum requirements for all personnel.

- Product Line Core – minimum requirements for all personnel in the fishing and re-entry product line, consisting of core processes, basic processes, products, services or equipment.

- Product Line Bolt-On – additional units for specialized equipment and job types within the fishing and re-entry product line.

Weatherford’s career paths are skills-based protocol, self-driven by employees, providing them a clear and structured way to advance their career. Employees, managers, and human resources interact throughout the career levels progression assuring the employee have attained the necessary knowledge and skills required for next step promotion.

Customer value added. All these processes and procedures in place, together with a non-negotiable leadership commitment to develop our workforce, assures Weatherford personnel deliver high-quality products and services to our clients that reduce costs and mitigate NPT, while ensuring the safety of everyone involved in Weatherford operations.

Unique Single-Trip Cut, Circulate, and Pull Service Saves Two Trips on Deepwater GOM Slot Recovery

Published: 01/23/2017

Slot recovery in deepwater GOM field

In a redevelopment and slot recovery operation in a subsea well in the mature Green Canyon field, Gulf of Mexico (GOM), an operator needed to P&A the nonproducing lower wellbore, sidetrack a new wellbore from the recovered slot, and use the existing subsea infrastructure to return the well to production. To maximize the economics of the slot recovery, the operator sought technology to reduce the number of trips needed to cut, circulate, and retrieve wellhead seals and casing.

Conventional methods require at least three trips or more if the casing cut and pull is unsuccessful after the first cut. Wellhead seals are recovered on the first trip. Then, the pipe cutter is run in on the second trip. On the third trip, the inline casing spear is run in, and the severed pipe is circulated up the annulus for recovery before the whipstock can be set.

Fewer trips with ProCISE system

For this slot recovery operation, Schlumberger recommended the ProCISE casing cutting and recovery system, which is an engineered assembly composed of multiple technologies designed to perform the P&A operation more efficiently. Prior to initiating a cut, the wellhead seals are pulled and mud displacement circulates out trapped annular gas. An inline casing spear is then engaged and an overpull check is performed to indicate a secure latch and to cut the casing in tension. Next, the WELL COMMANDER circulating tool from M-I SWACO, a Schlumberger company, is deactivated. Then circulation begins, transmitting rotation to the cutting assembly.

The multicycle pipe cutter, which allows multiple cuts per run, provides a contingency cutting system when multiple cut attempts are required, a common occurrence in P&A operations. In this well, imaging data showed settling of solids at the cutting location, which could require multiple cuts. The pipe cutter has three sets of blades that can perform multiple cuts in one trip, so if the casing cannot be freed on the first attempt, the cutting process can be repeated further up until the casing string is freed.

The pipe cutter is also equipped with a Flo-Tel downhole mechanical position indicator that provides pressure data at the surface for confirmation of a successful cut at each cutter position, eliminating the risk of pulling out of hole before the cutting operation is complete.

Once a successful cut is indicated, the latching spear is released, a unique high-pressure packoff is placed at the top of the cut casing string, and the inline casing spear is reengaged. Circulation is reestablished, and with the packoff set, returns come around the outside of the cut 9 5/8-in casing. This enables circulation of any cement, solids, and gas trapped in the annulus between the casing strings, all with established well control barriers in place. Once the cleanout circulation process is complete and the casing is confirmed to be free, the inline casing spear is unlatched and reengaged again so that the taper mill and multicycle pipe cutter are positioned inside the cut casing string. At this point, a trip out begins.

Successful cutting operation in one trip

The ProCISE casing cutting and recovery system enabled the operator to cut the casing free and recover the severed string at surface in a single trip while achieving an abandonment and subsequent kickoff depth of 5,005 ft. As a result, the operation was completed in one trip instead of three, eliminating two trips on the deepwater slot recovery. During the next phase of the slot recovery operation, the annulus was cleaned, and a TrackMaster CH cased hole whipstock system was set to exit the 13 3/8-in casing, sidetrack, and continue drilling to the new targeted production zone.

- Download PDF

Challenge: Reduce rig time required to cut, pull, and circulate around 9 5/8-in casing known to have annular solids and gas on a deepwater slot recovery operation in a GOM brownfield.

Solution: Use the ProCISE casing cutting and recovery system to perform P&A operations in a single trip.

Results:

- Retrieved wellhead seals on BHA without a need for an extra trip.

- Cut casing free and circulated out trapped gas and packed annular solids in a single trip with established well control.

- Maximized casing recovery to ensure whipstock setting depth was as per the new sidetrack drilling program, and there was no requirement to set the whipstock higher in the 13 3/8-in casing.

Place lost circulation and wellbore strengthening materials with an alternate circulation path.

- Software Support

- Incident Report

- Investor Relations

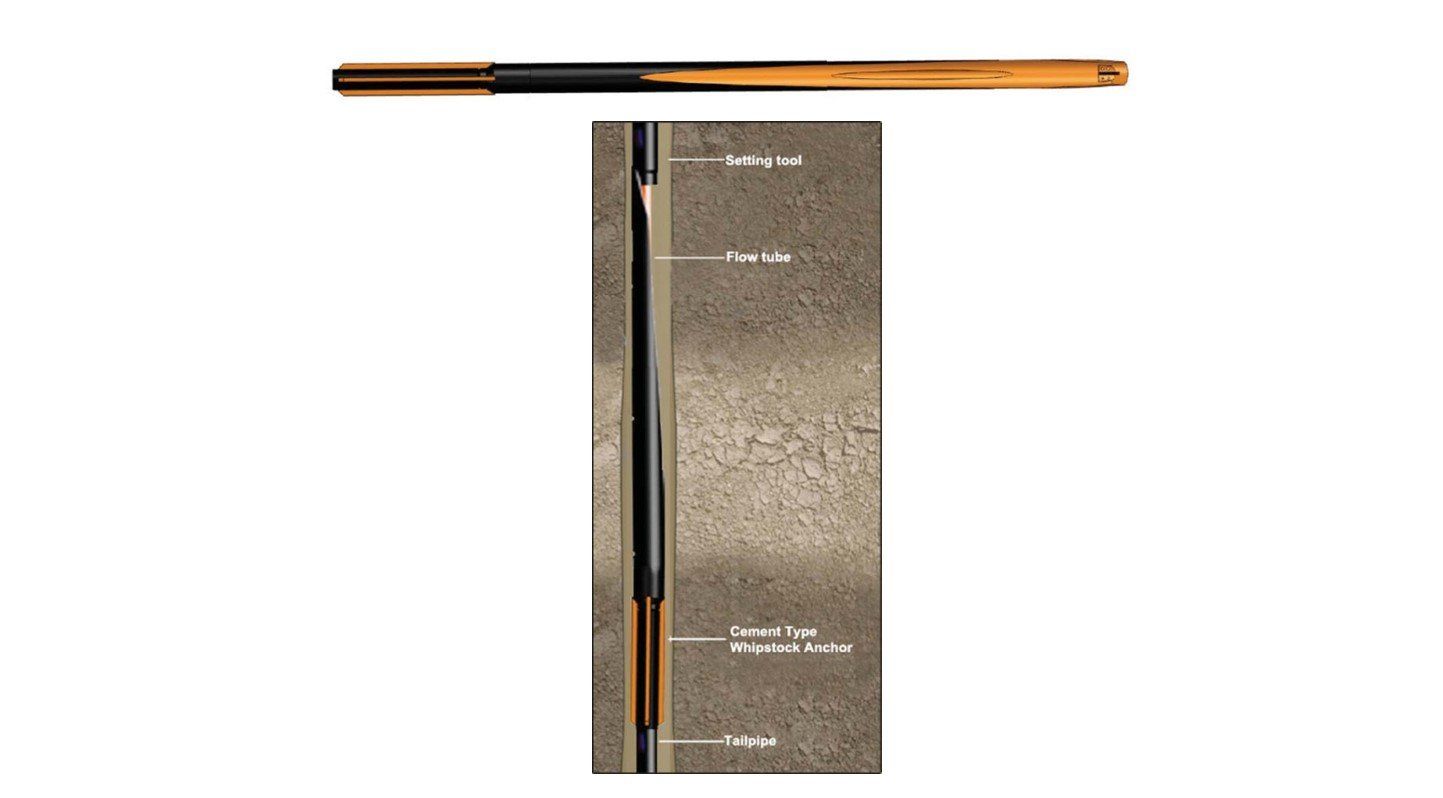

MasterWhipstock

- Single Trip Hydraulic Set (Permanent or Retrievable).

- Single Trip Mechanical Set (Permanent or Retrievable).

- Single Trip Openhole (Expandable Anchor).

- Cement Type Openhole.

- Inflatable type Whipstock.

Existing production range available from 5” to 20”, other sizes are available based on client specific requirement.

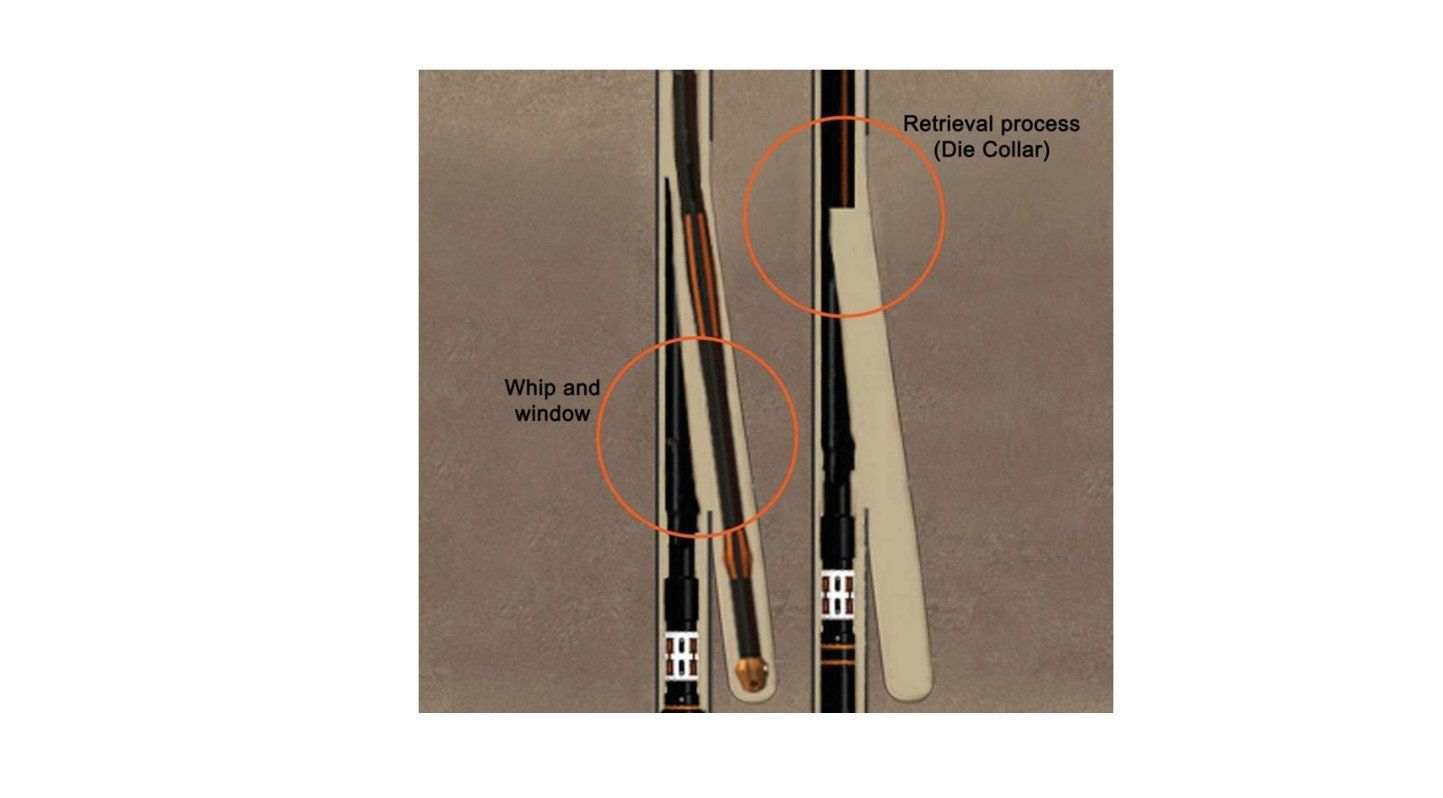

- Whipface: A concave shaped bar located at the top portion of the whipstock and is used to deflect the mill outwards.

- Anchor: The anchoring section is the ottom portion of the whipstock and is used to secure the whipstock in place and is connected to whipface by hinge system.

- Milling system.

- Field Proven anchor design. Whipface, hinge connectors and mills are available in various combinations to suit all applications.

- Mills are designed and dressed with Viper inserts and Tungsten Carbide for strength, optimum milling performance to minimize milling time, yet deliver optimum length and in-gauge window.

- The unique design of MasterWhipstock mills hook up provides protection of the shear mechanism from axial forces reducing the risk of premature shear while running in hole and facilitating ease of installation and reducing make up time due to the flexible design.

- Running tool for hydraulic actuation of the packer is a proven system used for many years.

- The retrieval hook and die collar are designed for retrieving the whip/anchor systems.

- All parts are manufactured from high strength and heat treated materials to provide strengths and durability.

Description

The whipface section is the part of the hipstock that actually directs the mills through the casing wall. MasterWhipstock’s Whipfaces have numbers of features, each of them having a specific function that contributes to the success of the whipstock operations

- Masterwhipstock offers different Whipfaces with angles from °2 to o3

- The MasterWhipface has a special design to assist the mill to cut casing uniformly and rapidly without “coring” problems.

- A unique robust “hook-up” system protects the shear bolt from torsional and tensional forces during running allowing the whipstock / BHA to pivot relative from each other for maximum ease when installing in wells with restrictions or high dog leg sections.

- Design of the profile ensures deflection of the mills laterally towards casing wall for a rapid cut out of the window achieving maximum length and gauge ofthewindow.

- A retrieval slot is machined and located in whipface for retrieval by hook.

- Top section of whip body is machined to allow clearance and engagementwith die collars and overshots.

- Milled slot in the back to house hydraulic system and protect while running. anufactured to API / ASME standards and specifications.

Hydraulic Set Anchor Packer

Design Advantages & Benefits

The Hydraulic Set Anchor Packer is available from 5” to 8/3-13” sizes

- Available in Permanent and Retrievable type options.

- The Hydraulic packer features tetra-directional slips that resist both upward and downward movement of the whipstock. Also it resists in right and left directions and prevents rotation of packer after it is set.

- Low setting pressure required.

- Designed to maximize the amount of hydraulic force generated directly into the seal and retaining slips.

- Ratchet system locks slips and seal in position.

- Copper cup seals provide an interference seal, preventing rubber element from creeping.

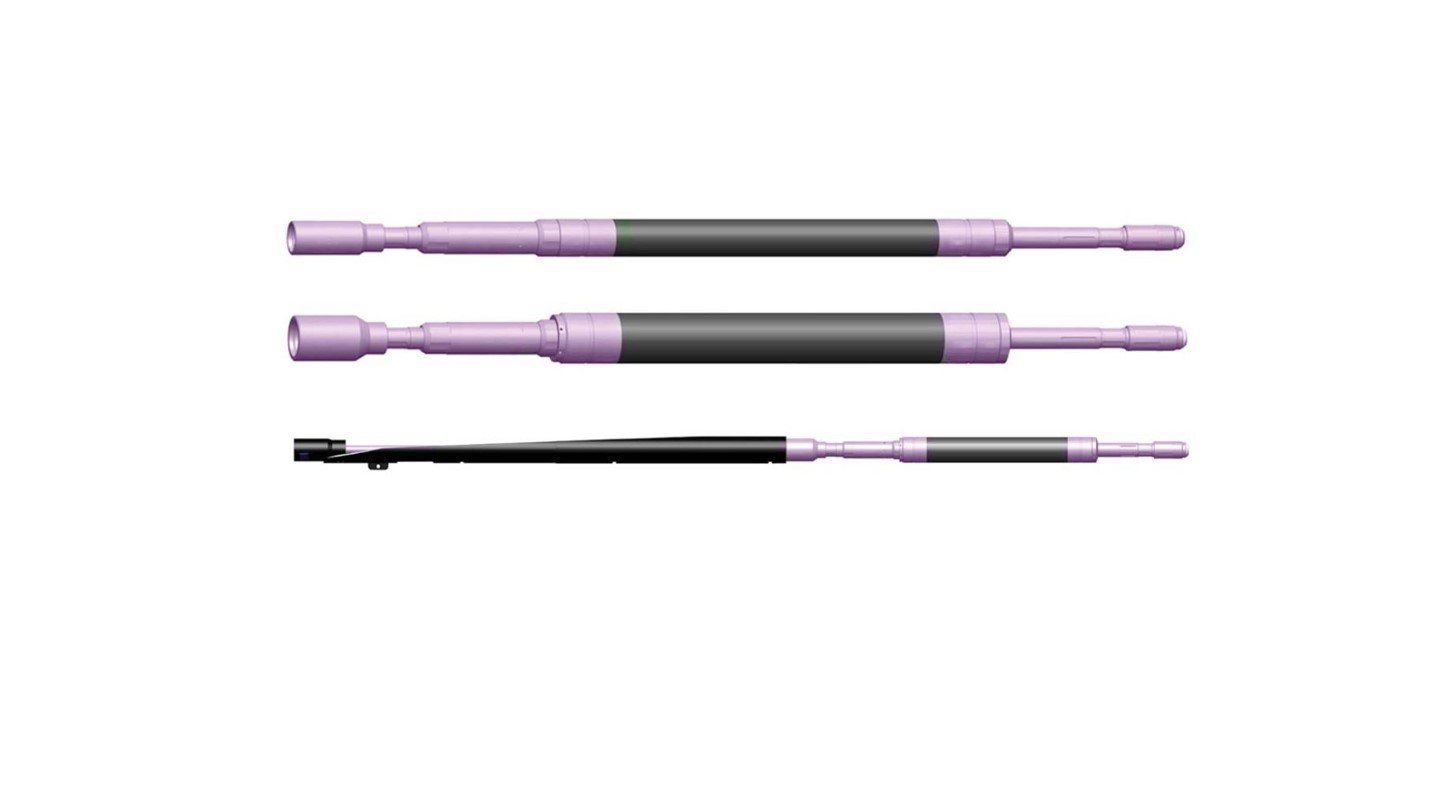

Mechanical Set Anchor

Single Grip Model: The single grip mechanical anchor is designed to firmly anchor the whipstock within the cased wellbore to enable sidetrack operations. The anchor is run in place using drill string along with the whipstock and the mill, and is set by tagging the bottom of the hole, cement plug or liner top. The anchor can then be properly positioned by pulling it up in the hole to the desired setting depth. Compression is then applied to the drill string to set the anchor and shear the mill’s shear screw. The anchor can easily be retrieved by latching on the whipstock and applying tension to the drill string.

Double Grip Model: The double grip mechanical anchor features bi-directional slips that resist both upward and downward movements of the whipstock. Similar to the single grip tool, the double grip anchor also give positive centering of the whipstock within the casing when in the set position. This mechanical anchor allows the mill’s shear bolt to be sheared in tension or compression without movement of the anchor. The anchor can easily be converted from a permanent to a retrievable version in the field.

Openhole Whipstock

Expandable Anchor Openhole Whipstock

The Expandable Anchor Openhole Whipstock is designed to be set in open hole, expanded the Anchor and set into position and drill out the window and rat hole in single trip. This type can be also cemented in place.

This Type of Whipstock is generally used to sidetrack in open hole when a hard formation will not allow the sidetracking. The Openhole Whipstock can be oriented with the use of orientation sub and survey equipment.

Advantages & Benefits

Advantages:

- Can be used with or without Cement.

- Positive kick-off point in hard formations.

- Ramp to build and maintain deviation in unconsolidated formations.

- Eliminates total reliance on cement integrity in areas where cement plugs are difficult to achieve.

- Single Trip System when not using cement.

- Potential savings in cement costing.

- Reliable in wide range offormations.

- Easy to set and side track.

- Cost savings in time waiting on cement and in time spent “time-drilling”.

- Reduces the need for multiple cement jobs.

Cement Type Whipstock

Cement is pumped from the surface through the drill string, setting tool and whipstock to the bottom of the whipstock. Once the cement reaches below the whipstock, the whipstock is then lowered, set inside the cement and then allowed to harden in place. After the cement is hard, a drill bit is used to continue drilling down the concave face ofthe whipstock

- Ramp to build and maintain deviation in unconsolidated formations

Inflatable Openhole Whipstock

The Inflatable Open Hole Whipstock Packer is used below a Whipstock Assembly to provide solid anchoring and support. In addition, the tool also provides zonal isolation in Openhole or in casing. Inflatable packer elements for these tools are 66 inches in length with 4 foot seal lengths. High strength aircraft cable is used to provide expansion characteristics in washed out or irregular well bores. Cable reinforcement allows these elements to return very close to the original run-in diameter.

Retrievable Whipstock

Retrievable Whipstock is a specialized tool that can be deployed for multi-sidetracking in Openhole and opening multiple windows in cased hole.

Applications:

- Cost effective sidetracking.

- Avoids drilling new infill wells.

- Drill small rat holes for formation tests.

- Re-entry in exiting well.

- To drill multi-lateral well

- Easily Retrievable.

- Mechanical and Hydraulic Set Models.

- Reduces Cost and Time.

- Only One Trip Requires to Mill Casing Exit and Drill Pilot Hole.

- Integrity with MWD or Gyro for Orientation.

- Provides Low Dogleg Severity Across the Exit.

Hydraulic Running Tools

- Utilizes the proven piston type running tool.

- Clean oil reservoir promotes trouble free acting of hydraulic packers, separated by a reliable debris barrier

All Rights Reserved | Techmaster Tools Inc.

SIGN UP FOR OUR NEWSLETTER

- Energy Transition Energy technology to help the industry advance on the path to net-zero

- Hydrogen Technologies Advanced technologies to accelerate hydrogen deployment

- Geothermal Solutions Experience and expertise to redefine possibilities in geothermal

- Carbon Capture, Utilization, and Storage (CCUS) Integrated suite of solutions to capture, process, store, and monitor CO2 emissions

- Emissions Abatement Solutions to monitor and reduce emissions from industrial operations

- Remote Operations Digital operations, monitoring and testing capabilities to serve critical industries

- AI by BakerHughesC3.ai Enterprise-scale artificial intelligence for energy operations

- Liquefied Natural Gas Industry leading solutions for long-term reliability, availability, and project success

- Industrial Technology Solutions to improve efficiency and uptime in processing and manufacturing industries

- Subsea Connect Subsea solutions to enhance production, maximize recovery, and reduce TOTEX

- Industrial Solutions Flexible and connected digital solutions for industrial machines, equipment, and systems

- Mature Assets Solutions Reviving mature Assets and accelerating impact through integrated solutions

- Alternative Business Models

- Channel Partners

- Direct Sales

- Onshore Composite Pipe

- Coring Services

- GaffneyCline

- Reservoir Technical Services

- Logging-While-Drilling Services

- Surface Logging Services

- Wireline Cased-Hole Logging

- Wireline Openhole Logging

- Drill Stem Testing (DST)

- Wireline Mechanical Services

- Perforating

- Wireline Well Integrity Evaluation

- Geomechanics

- Geophysics Services

- Microseismic Services

- Petroleum Engineering Services

- Petrophysics

- Production Analysis Services

- Reservoir Engineering Services

- Reservoir Navigation Services

- Pre-Commissioning & Maintenance

- In-line Inspection

- Casing & Lining Drilling Services

- Drilling Automation

- Coiled Tubing Drilling Services

- Directional Drilling Services

- Drilling Fluids

- Drilling Optimization Services

- Measurement-While-Drilling Services

- Wellheads & Connectors

- Maximizing Return on Efficiency

- Completion Fluids

- Intelligent Completion Systems & Flow Assurance

- Gas Lift Systems

- Isolation Valves

- Liner Hanger Systems

- Multilateral Systems

- Multistage Completions

- Sand Control

- Stimulation & Fracturing

- Subsurface Flow Control

- Subsurface Safety Systems

- Tubular Services

- Well Monitoring and Analytics

- Artificial Lift

- Asset Integrity Management

- Flow Assurance

- Intelligent Chemistry

- Production Optimization

- Production Solutions

- Core Competencies

- Integrated Well Construction

- Integrated Coiled-Tubing Services

- Integrated Intervention and Production Enhancement Solutions

- Integrated Well Abandonment

- Gas Processing and LNG

- Pipeline Management

- Refining Services

- Terminals, Blending, and Transportation Services

- Flexible pipe systems

- Subsea Connect

- Subsea Production Systems

- Coiled Tubing Systems & Services

- Fishing Services

- Plug & Abandonment Services

- Remedial Completions

- Smart Intervention

- Thru-tubing Intervention

- Workover Systems

- Carbon capture and injection wellhead solutions

- Compact multibowl wellhead solutions

- Conventional wellhead systems

- Geothermal wellhead solutions

- Mudline suspension solutions

- Pipeline Maintenance Services & Decommissioning

- Subsurface Modeling

- Well Planning

- Advanced Analytics

- Well Construction

- Data Management

- Well Production

- Remote Operations

- Edge & Compute

- Aeroderivative Technology

- Frame Technology

- NovaLT Technology

- Steam turbines for Mechanical Drive

- Steam turbines for power generation

- Axial Compressors

- BCL Vertically Split Compressors

- Blue-C Compressor

- High Pressure Ratio Compressor

- ICL Zero-Emissions Integrated Compressors

- MCL Horizontally Split Compressors

- PCL Pipeline Compressors

- SRL Integrally Geared Compressors

- API 618 Reciprocating Compressors

- LDPE Hypercompressors

- 2-pole, air-cooled generators

- 4-pole, air-cooled generators

- Generator control and protection systems

- Harrington Generators International (HGI)

- Mobile and trailer-mounted generators

- PRISMIC excitation systems

- PRISMIC power management systems

- Synchronous condensers

- Synchronous motors

- Gear Couplings

- Gears Services

- High-Speed Epicyclic Gearboxes

- High-Speed Parallel Shaft Gearboxes

- Integrally Geared Solutions

- Low-Speed Gearboxes

- Marine Gears

- Air Cooled Heat Exchangers

- Hot Gas Expanders

- Turboexpander Compressors

- Turboexpander Generators

- Advanced Digital Services

- Remote Field Service Support

- Remote Operations Support

- Remote Outage Preparation

- Valve Lifecycle Management

- Remote Training

- Virtual String Test

- Advanced Services

- Knowledge Services

- Maintenance Services

- Total Lifecycle Services

- BB1 DVS/DVE/BFD Pumps

- BB2 DVSHF/THF/DS-THF Radially Split Pumps

- BB3 MSN/MSND Multistage Axially Split Pumps

- BB5 DDHF Multi-Stage Centrifugal Pumps

- BB5 DDHFM Radially Split Multistage Pumps

- Saturne Pump

- Baker Hughes University

- Customer Training

- BakerHughesC3.ai BakerHughesC3.ai Enterprise-scale AI to make energy operations safer, cleaner and more efficient Explore

- NDT Software

- Cyber Security Services

- Downhole Sensors

- Flame Detectors

- Flare Flow Meters

- Flare Solutions

- Custody Transfer, Allocation, Leak Detection

- Portable Flow Meters

- Process Flow Meters

- Industrial Asset Inspection

- Industrial Radiography and CT

- Machinery Asset Health & Consulting Services

- Machinery Diagnostic Services

- Distributed Vibration Monitoring & Machine Protection

- Online Condition Monitoring

- Portables & Diagnostic

- Non-Destructive Testing

- Nuclear Measurement Solutions

- Configurable Pressure Sensing Solutions

- Digital Communication Pressure Sensors

- Flight Qualified Aerospace Pressure Sensors

- OEM Custom Pressure Sensors

- Moisture Analyzers

- Oxygen & Gas Analyzers

- Portable Moisture Analyzers

- Radiation Measurement & Monitoring

- Remote Monitoring & Diagnostics

- Remote Visual Inspection (RVI)

- Robotic Inspection

- Roller Bearing Condition Monitoring

- Acceleration & Velocity Sensors

- Hydro Sensors

- Pressure Sensors

- Proximity Sensors

- Sensor Accessories, Housings & Test Kits

- Transmitters

- Velocity Sensors

- Wireless - Ranger Pro

- Supporting Services Agreements

- System 1's Performance and Predictive Emissions Monitoring System (PEMS)

- System Design Installation

- Air Data Test Sets

- Calibration Software

- Modular Pressure Controllers

- Ultrasonic Testing

- Bently Training

- Machinery Diagnostics Services

- Monitoring Systems

- System 1 Condition Monitoring Software

- Test and Calibration Instruments

- Assured Pressure Support Services

- Flare Management

- Flow Meters

- Process Analyzers

- Panametrics Services

- Waygate Technologies Robotics

- Company Leadership

- io consulting

- Awards and Recognition

- Upcoming Events

- Event Proceedings

- Sustainability at Baker Hughes

- Diversity, equity, and inclusion

- Planet Planet We are committed to operating with sound environmental practices to protect the planet. Explore

- Principles Principles Our culture promotes and encourages employees to act with integrity, responsibility, and compliance every day. Explore

- Reports & Policies

- Sustainability Strategy

- Energy Forward Stories

- Case Study Library

- Preference Center

- Resources Center

- Supplier Resources

- Channel Partner Resources

- Customer Resources

- 2023 Annual Report

- Baker Hughes in Deutschland

- Baker Hughes Italia

- Florence Learning Center

X-treme WindowMaster whipstock system

Get faster, cleaner, better sidetracks.

Join Waqas Munir, Global Product Line Manager, Conventional Fishing and Casing Exits, as he highlights this exciting new technology—the X-treme™ WindowMaster™ whipstock system. This new system lets you sidetrack three times faster and reduce rig time by as much as 50 percent over conventional methods, all while eliminating a dedicated clean-out run.

- Provides limitless tripping operations

- Removes limitations with unlimited reorientation and resetting of whipstock

- Eliminates extra clean out runs

Applications

- Sidetrack operations

The X-treme™ Windowmaster ™ whipstock system provides quicker, more efficient sidetracks, and is capable of milling a window in a single trip.

The X-treme Windowmaster system lets you sidetrack three times faster and reduce rig time by as much as 50 percent over conventional methods, all while eliminating a dedicated clean-out run.

Dramatically reduce NPT

- Set at any depth, hydraulically or annularly, without additional tools – eliminating the need to trip out and use a back-up system

Dramatically reduce drilling time

- Set the whipstock in stubborn casings, at greater depths, with the ability to push and pull

- Work through restrictions and trip in hole with virtually unlimited tripping speed, with no need for a prior clean-out operation

- Make deeper exit points and shorter laterals by passing through restrictions such as casing ovality or deformation

Eliminate risky red zone exposure during assembly

- Improve handling and operation – and save up to three hours per job – with a design that requires only a standard drill-pipe connection to mate the lead mill and connector

The X-treme Windowmaster system mills a perfect window with extended rat holes every time – so there’s no requirement for additional trips to ream or polish the casing exit window.

Mill a cleaner window with:

- A hybrid drill bit that’s specifically engineered for milling in any rock type or casing grade

- The proprietary Baker Hughes advanced milling technology combined with the proprietary Baker Hughes PathMaker™ polycrystalline diamond cutters

The X-treme Windowmaster system collects downhole data with the Baker Hughes xSight™ analytics service for casing exits to help you with pre-job planning and post-job analysis.

Real-time downhole data lets you:

- Optimize milling parameters to get through tight spots in the wellbore

- Monitor and confirm the load so that you know when the milling BHA has broken free from the whipstock ramp

How the X-treme WindowMaster whipstock system works

A proprietary connector replaces the traditional bolt, eliminating the operational limitations like reduced or low tripping speed, soft motion starts and stops, problems with rotation, and weight limitations typically put in place to avoid failure points and breakage.

This system offers a very robust design with few moving parts, and includes built-in redundant mechanical activation. The anchor can be set in any direction and, if needed, can be un-set and re-oriented/re-set after initial activation. A sacrificial scraper can also be installed to scrape the setting area. Once at depth, the well is closed in and pressure is applied on the annulus to activate the anchor. The anchor is then fully set by use of weigh, and rotation is applied to shear the milling assembly free from the connector. The milling assembly has also undergone significant design changes to ensure effective and optimized milling performance.

Choose the only whipstock system that can deliver reliable results without sacrificing time and performance. Call your local Baker Hughes representative to learn how the Xtreme WindowMaster whipstock system can deliver a reliable one-trip casing exit solution—every time.

Get in touch with an expert.

Discover the latest people & innovations shaping our industry.

Solving the industry's toughest challenges.

- Show more sharing options

- Copy Link URL Copied!

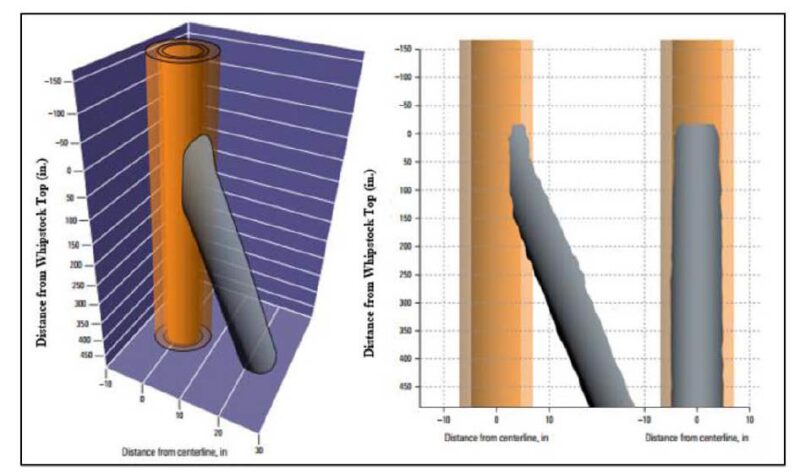

Digital Planning and Modeling Enhances Performance of Whipstock Sidetracking System in Complex Wells

Combined with advances in whipstock and milling technologies, digital technologies are enabling operators to plan and conduct sidetracking operations with improved flexibility, precision, and efficiency..

Sidetracking, the long-proven technique of setting a whipstock to exit an original wellbore to tap an alternate production zone or bypass a downhole obstruction, is relying on digital technology to enhance performance in increasingly challenging formations and complex well trajectories.

Combined with advances in whipstock and milling technologies, the digital component is enabling operators to plan and conduct sidetracking operations with greater flexibility, precision, and efficiency—important objectives considering the variety of scenarios where the procedure is used. In open holes where toolstring failures have occurred, whipstocks, often are set to sidetrack around a lost bottomhole assembly (BHA) to recover the drilling program.

In cased holes experiencing reservoir depletion, a whipstock system can perform a slot recovery, drilling ahead to a different part of the reservoir using as much of the original wellbore structure as possible. Sidetracking also enables slot recovery on offshore platforms, which are restricted by the number of well slots from which to drill. In tight unconventional reservoirs, whipstocks are set to sidetrack and build long laterals from a vertical wellbore. Multilateral wells, common in regions where surface infrastructure is restricted, feature as many as eight wells sidetracked from a single mother wellbore.

To meet the realities of 21 st century hydrocarbon recovery, optimized tool design, robust materials, and pre-planning regimens that use the latest simulation and visualization software are now essential. The recently launched TrackMaster Select modular whipstock sidetracking system provides full-gauge windows for casing exit operations. The system features a single-piece mill engineered with an optimized cutting structure, replacing the random crushed carbide cutters with a cutting structure forged into the tool body. The structure incorporates individual cylindrical cutting inserts brazed onto the blade. The forged body design eliminates the welding process, putting far less heat into the tool and increasing mill fatigue life by about 30%.

The result is a stronger, faster, and more reliable sidetracking system that can perform challenging milling jobs involving heavy casing, high chrome content, and longer milling times in a single run. The modular system, which enables applications for single or multiple casing exits, openhole sidetracking for offshore extended windows and multilateral wells, was used to successfully perform a single-trip dual-casing exit operation in a carbonate field in the Middle East.

Digital Solutions for Planning, Modeling

The whipstock sidetracking system works in concert with the IDEAS integrated dynamic design and analysis platform, which provides 4D, time-based simulations that capture the entire drillstring and wellbore geometry to ensure precise modeling of cutting interfaces for drilling rock and milling metal. Whipstock retrievability is improved with an optimized hook slot location, while the new mill design preserves the thickness at the top of the whipstock for greater reliability.

The design and analysis platform offers a suite of solid mechanics and programs that reveal bit-to-rock and mill-to-metal interactions in a virtual environmental for real-time customization. Collaboration with the customer establishes baseline performance and goals and incorporates modeling from a variety of tools, including motors, mills, and pipe cuttings. Cutting interface data are attained from scrape and insert indentation tests conducted in the materials mechanics labs. Models are validated using theoretical calculations and commercial finite element packages. Pre-job planning with the platform has been shown to minimize doglegs and predict consistent well trajectory with 97–98% accuracy compared to actual results.

The whipstock sidetracking system is also supported by the DrillPlan coherent well construction planning solution, which enables optimization of the BHA model window geometry, and performs following string pass-through and milling simulations, along with bending stress and downhole dynamics analysis.

The planning solution integrates into one platform, three software services—the i-DRILL integrated dynamic system analysis service, which uses predictive modeling to minimize vibration and slip/stick and optimize BHA performance; the WhipSim whipstock simulation software to model the milling operation and window geometry and the Runner drillstring analysis program, which provides a model for analyzing surface parameters, torque-and-drag and settings operations for anchors and shear bolt activation, and real-time analysis of modeled vs. actual parameters. The comprehensive service maximizes overall well planning and provides the ability to make adjustments during the operation to ensure the exit widow expedites passage of the BHA.

Sidetracking Through Dual Casing

In 2017, Kuwait Oil Company (KOC) collaborated with Schlumberger to successfully plan, model, and deploy the modular whipstock sidetracking system as part of a slot recovery operation in the Raudhatain carbonate field of northern Kuwait. Sidetracking in the field is commonly used to improve production in old wells. Formation analysis, BHA analysis casing and centralizer placements, wellbore inclination, dogleg severity, and orientation are critical for ensuring a successful sidetracking job.

In this case, the operator needed to sidetrack through dual casing in an existing wellbore in a challenging, high-shock carbonate environment. Carbonate formations can be very damaging to mill systems, especially in situations with dual casing. Key objectives were to mill a high-quality, full-gauge window and exit two strings of casing with minimal shock and vibration in one trip. Window quality was especially critical for enabling subsequent BHAs to pass through without incurring costly and risky tripping operations.

The job involved sidetracking the existing wellbore drilled with 9 5/8-in. and 13 3/8-in. casing strings. During the planning phase, the BHA was modeled using a finite-element analysis (FEA)-based modeling system and the whipstock simulation software. The mill operation and cutting structure were modeled using the IDEAS platform to determine the configuration that would generate the least amount of vibration.

During the planning phase, several issues were evaluated, including the feasibility of using a bi-mill vs. a tri-mill BHA. The bi-mill BHA was eventually selected to mill the two casing strings at the whipstock setting depth. Placement of the centralizers and casing collars along the length of the casing at the kickoff point was analyzed to ensure the centralizers or casing collars were not inadvertently milled. The dimensions of the whipstock slide and mill position during the milling operators also were considered. Torque-and-drag was modeled before the job to verify that sufficient weight was available to shear the shear bolt. These analyses enabled the engineers to finalize a reliable parameter road map. The whipstock setting depth was determined by studying the exact points where the lead mill initiated the cut at each casing string.

The whipstock simulation software, which calculates dogleg severity for a liner or BHA pass-through as well as the stresses of the BHA, was used to check the bending moments, ensuring that the completion strings were not impacted by the dogleg across the whipstock. Engineers also reviewed the total cuttings volume generated from the milling operation. Cuttings were collected from the ditch magnets periodically throughout the operation so that the quality of the window could be evaluated by comparing the total volume of metal cuttings with the volume simulated using the whipstock simulation software.

Collaboration between the two companies ensured the challenging sidetracking job met the operator’s objectives efficiently and safely. For an operation that typically would be accomplished in two or three runs, the whipstock sidetracking system, enhanced with proactive planning, and modeling and simulation technologies, successfully performed the complex dual-casing sidetrack in a single run, significantly reducing time and cost. Planning using the design and analysis platform and whipstock simulation software were key to mitigating BHA shock loading. The project enhanced KOC’s confidence in the FEA platform’s ability to accurately identify the basis of damaging vibrations, paving the way to implement the approach in subsequent wells.

- Mission Vision Values

- Transaction Updates

- History Timeline

- Open and Cased Hole Fishing

TrackMaster* Select Whipstock System

- TrackMaster* OH-C Whipstock and Cementing System

- ProCISE™ Casing Cutting and Recovery System

- PullMaster Hydraulic Pulling Unit

- ProLATCH™ Wellhead Retrieval System

- ProMILL™ Milling And Underreaming System

- ProMILL Duo™ (Dual Casing Section Mill)

- Milling and Cutting Structures

- Section Milling

- Casing Milling

- Underreaming

- Casing Cutting

- Casing Cleaning

- Debris Management

- Combo Efficiencies

- Wellhead and Riser Cleaning

- Circulation Control and Accessories

- Thru Tubing (TT) Services

- FiberLine Technology

- DRILCO: Tubular Services

- Thomas Tools: Rental Equipment

- Engineering Services

- Geothermal Solutions

- Sustained Casing Pressure Remediation Solutions

- Document Library

Applications

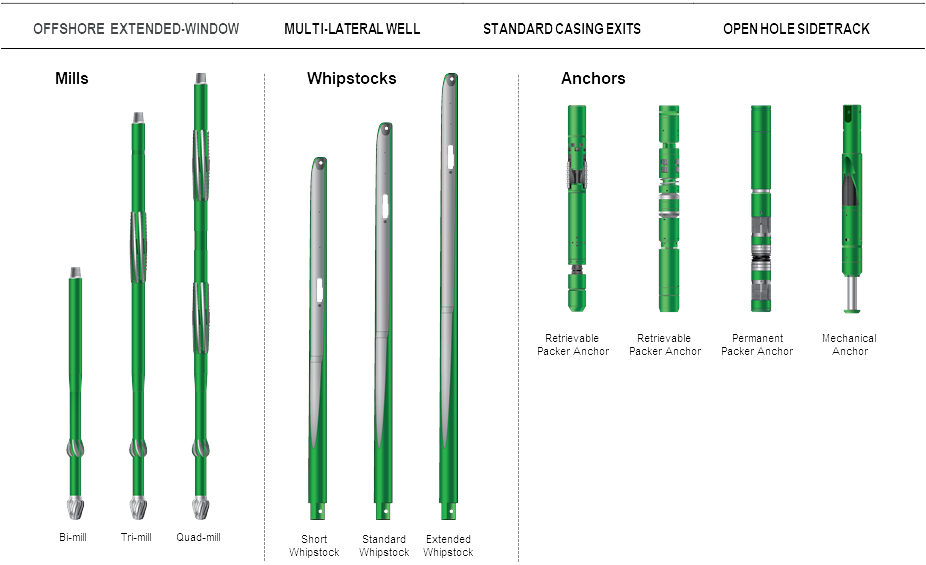

Three categories define the configuration options for the TrackMaster* Select system:

CONVENTIONAL SIDETRACKS

- Single casing

- Hard formation

- Extended rathole

- Elongated window

ADVANCED SIDETRACKS

- Heavy wall, high-strength casing

- Corrosion-resistant alloy casing

- Lowside exit

- Dual and triple casing

SPECIALIZED SIDETRACKS

- Custom multi-lateral junctions

- Flow by access configurations

Operational Drivers

- Multi-lateral

- Production increase

- Cost reduction

- Obstruction

- Collapsed casing

- Directional issue

TrackMaster * Select

- A History of Innovation

- Unrivaled Experience

- Global Presence

*Mark of Wellbore Integrity Solutions

- Application-specific configuration options

- One-trip solution saves time and cost

- Comprehensive planning process

- Proprietary modeling software to predict window geometry and BHA pass-through

- Increased durability and reliability

- Improved milling efficiency in a broad range of casing and formations

Document Downloads

- Bi-mill, tri-mill and quad-mill configurations

- Customized cutting structures for all casing and formation types

- Fabricated and integral mill designs

- Unique multi-ramp profile offers rapid cut out and extended full gauge window

- Integral retrieval slot for whipstock recovery when required

- Configurations options for multi-lateral and flow by applications

- Anti-rotation and high-axial-load slip design

- Hydraulic and mechanical set actuation

- High-pressure packer element option available

- Large slip areas to reduce casing stress and provide more positive anchor set

need Assistance?

Join our mailing list.

" * " indicates required fields

Products & Services

GLOBAL HEADQUARTERS

Wellbore Integrity Solutions 1310 Rankin Building 18 Houston, TX 77073 USA

281-975-2500

© 2024 Wellbore Integrity Solutions — All Rights Reserved. Privacy Policy

Title: Whipstock assembly with hydraulically set anchor

- Full Record

- Other Related Research

This patent describes a single-trip whipstock assembly for diverting a well bore for continued production. It comprises: a hydraulically set anchor; a whip attached to an upper end of the anchor; and means for running the whipstock assembly into the well bore; wherein the whipstock assembly is run into the well bore and set within the well bore in a single trip by setting the anchor, the anchor including: an inner mandrel; a slip assembly mounted to the mandrel; and interlock means for preventing retraction of the slip elements form the cased well bore upon elimination of hydraulic fluid pressure. This patent also describes a method of running and setting a whipstock assembly into a cased well bore for changing the direction of a drilling in a single trip. It comprises: running a whipstock assembly into the cased well bore; an inner mandrel having a fluid passageway selectively communication with the hydraulic fluid supply means; a piston cylinder in fluid communication with the fluid passageway of the mandrel; a slip assembly mounted to the mandrel; and interlock means for preventing retraction of the slip elements form the cased well bore upon elimination of hydraulic fluid pressure; positioning the whip stock more » assembly within the cased well bore at the location for change of direction; setting the whipstock assembly by supplying hydraulic fluid through the supplying means to set the anchor within the cased well bore without sealing the well bore; and running a mill along the whipstock into engagement with the cased well bore to mill an aperture in the casing to facilitate changing the direction of drilling from the cased well bore. « less

Citation Formats

- CSV / Excel

Similar records in OSTI.GOV collections:

- Similar Records

Subsea Water-Cut Meter

- See all Products

Driving MPD adoption with ... 01/15/2024

Weatherford’s well construction platform ... 11/14/2023, weatherford, honeywell collaborate on ... 11/07/2023.

- Visit our Newsroom

- Visit Investor News

Real Results around the world

- AlphaST SalesCard pdf

- AlphaST™ Openhole Sidetrack System Executes Operation in One Trip to Save 46 Hours of Rig Time PDF

- AlphaST™ System Saves 10 Days Compared to the Previous Cement Plug Sidetrack PDF

- AlphaST™ System Saves 29 Hours of Rig Time By Delivering a Single-Trip Openhole Sidetrack PDF

- AlphaST™ Single-Trip Openhole Cement and Sidetrack System pdf

THE WORLD’S ONLY SINGLE-TRIP OPENHOLE CEMENTING AND SIDETRACK SYSTEM

Single-Trip Cementing and Sidetrack System

Unleash your capabilities

We develop technologies that others don't so our customers can do what others can't. For more than four decades we have led the industry's re-entry market. We combined our legacy with excellence in engineering to give you an unbeatable single-trip re-entry solution.

The AlphaST ® single-trip openhole cementing and sidetrack system enables you to cement, anchor the whipstock, and mill off formation—without the need to set cement plugs or wait on cement to cure. The system drives down sidetracking costs, eliminates the need for multiple trips in hole, and avoids costly cementing operations for a variety of applications.

The AlphaST Advantage

Cement, anchor, and drill off in one run

We engineered the AlphaST system for efficiency. The system enables you to set the whipstock, convey cement if necessary, and drill off in one run without waiting for cement to cure. By using our IPP ® inflatable production packer to anchor the whipstock in the open hole, you can begin drilling off before the cement sets. A lead mill and flex mill initiate the kickoff and facilitate a quick departure from the original wellbore.

IN A SINGLE TRIP

FLEXIBILITY

Drill past a fish or around a collapsed borehole, straighten crooked holes, or bypass cement plugs. A slim, reinforced inflatable packer enables you to work past borehole restrictions and reach your kickoff point.

RELIABILITY

A rugged, reinforced packer with a full 360° of contact exerts great holding force across a wide range of hole sizes and conditions. This field-proven packer gives you more control over the kickoff point. The result is unmatched reliability.

Kick off as soon as you set the packer. Two mills on the bottomhole assembly (BHA) facilitate a quick departure from the old wellbore—and the single-angle whipstock concave sets up a smooth transition into the sidetrack.

Anchor the whipstock with an inflatable packer

Achieve well integrity with a cement abandonment plug

Save days of rig time

Avoid time drilling and the risk of having to re-cement and re-drill

Remain in absolute control of the kickoff point and direction

Eliminate waiting for cement by using a packer as a barrier

Find out how our system enhances operations

Real Results

Our AlphaST sidetrack system delivers optimal performance, time savings, and cost reductions for customers around the world—even in the most challenging environments.

Permian Basin, USA

SAVED 5 DAYS OF RIG TIME FOR MAJOR OPERATOR

Wyoming, USA

SAVED 46 HOURS OF RIG TIME BY EXECUTING OPERATION IN 1 TRIP

The AlphaST single-trip openhole cementing and sidetrack system enables you to achieve success using a reliable and cost-effective solution. To learn how our system can enhance your operations, please complete the contact form below. One of our experts will be in touch.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.

IMAGES

VIDEO

COMMENTS

The single-trip whipstocks are more expensive, but the savings in rig time may offset the additional cost of the single-trip whipstock (also check oil well drilling well cost per foot). Many whipstocks are retrievable for drilling multilaterals wells. Running procedures vary with every whipstock, and the manufacturer should be consulted.

Ensure reliable sidetracks in your openhole wells with whipstock systems from Baker Hughes. In a single trip downhole, our whipstock systems give you reliable control over where the mill exits your wellbore—eliminating the risks of missed runs and minimizing the time for cement plugs to set. Ensure consistent and precise sidetracking

casing exit performed in one trip. Single-trip, dual-casing exit performed for the first time in India. MODULAR WHIPSTOCK SIDETRACKING SYSTEM . SAVES 4 DAYS IN SOFT SHALE FORMATION The TrackMaster Select system was used to perform the first single-trip, dual-casing exit offshore India. More than 22.9 ft [7 m] of casing was milled

Graco MasterTech redefines the cased wellbore exit landscape with its cutting-edge, single-trip whipstock system. This isn't just a solution; it's a dynamic whipstock system meticulously crafted to set new industry benchmarks. With its cost-effective approach for exiting cased wellbores, Graco's MasterTech's compact design, short ...

first one-trip Level 4 multilateral system, it incorporates the proven QuickCut™ milling system for orientation of the whipstock-anchor assembly, milling of the window, and drilling of the rathole in a single run. The unique, multi-purpose hollow whipstock is used in the milling, drilling, and completion phases.

Openhole Whipstock System Screw-In Type Anchor Weatherford's openhole whipstock system is a single trip, screw-in style, concave assembly that uses multiple attachment options to provide anchoring of the whipstock assembly in an openhole environment. The specific anchoring attachment component is determined by the particular wellbore

The single-angle 3° whipstock creates a smooth transition to eliminate BHA geometry issues on subsequent trips. A lead mill and flex mill initiate the kickoff. This reliable, field-proven openhole whipstock, anchor, and milling system enables operators to access the pay zone in the shortest possible route. The QuickCut single-trip openhole ...

WhipStock Services John M. Phillips Single Trip WhipStock Service is available for casing exits up to 16-inch OD casing and may be ordered with mechanical or hydraulic set option. This WhipStock service features integral blade mills with advanced carbide inserts designed to exit single or dual string programs in one trip and may be retrieved if necessary

Advantages. - One trip whipstock. - Our whipstock, although very simple in design, provide a reliable anchor. - The use of our whipstocks allows the cutting of the window in casings without any cementing or similar operations with inclinations up to 90º. - The double mill cutter is reinforced with metal-ceramic composition and reinforced by ...

whipstock system The X-treme™ Windowmaster™ whipstock system provides quicker, more efficient sidetracks, and is capable of milling a window in a single trip. FASTER The X-treme Windowmaster system lets you sidetrack three times faster and reduce rig time by as much as 50 percent over conventional methods, all while •

advanced technologies, including Weatherford's SAQC single-trip, milling system and a unique, single-trip hollow whipstock. A combination of several advanced technologies, our OneTrip StarBurst system received two prestigious industry awards for innovation in 2009. In both cases, the review panels consisted of third-party industry experts.

whipstock in a casing collar-free area • Improve milling and overall efficiency in a whipstock casing exits operation Results • Milled dual casing window in seven hours and 35-ft rathole in less than one hour • Saved operator rig time with single trip whipstock system, an estimated $1.5 million USD • Reduced operator cost by

Weatherford International announced a milestone of 113 consecutive cased hole whipstock jobs completed in California in a single trip. The installation success began with the first run in February ...

Cut casing free and circulated out trapped gas and packed annular solids in a single trip with established well control. Maximized casing recovery to ensure whipstock setting depth was as per the new sidetrack drilling program, and there was no requirement to set the whipstock higher in the 13 3/8-in casing.

Whipstock is an effective, cost-efficient tool for sidetracking from an existing wellbore. Sidetracking can be accomplished in open hole or throughout a single or more casing layer. In a cased hole, the whipstock deflects the mill to create an opening for the drill string in the desired direction. In an open hole, the whipstock deflects the ...

The X-treme™ Windowmaster™ whipstock system provides quicker, more efficient sidetracks, and is capable of milling a window in a single trip.. Faster. The X-treme Windowmaster system lets you sidetrack three times faster and reduce rig time by as much as 50 percent over conventional methods, all while eliminating a dedicated clean-out run.

Digital Solutions for Planning, Modeling. The whipstock sidetracking system works in concert with the IDEAS integrated dynamic design and analysis platform, which provides 4D, time-based simulations that capture the entire drillstring and wellbore geometry to ensure precise modeling of cutting interfaces for drilling rock and milling metal.

to get to your kickoff point. And. our specially designed fl ow tube beneath the concave platform lets you set a cement barrier before you anchor the whipstock. you set the packer. Two mills on the BHA facilitate a quick departure from the old well bore—and the single-angle whipstock concave sets up a smooth transition into the sidetrack.

Applications Three categories define the configuration options for the TrackMaster* Select system: CONVENTIONAL SIDETRACKS Single casing Hard formation Extended rathole Elongated window ADVANCED SIDETRACKS Heavy wall, high-strength casing Corrosion-resistant alloy casing Lowside exit Dual and triple casing SPECIALIZED SIDETRACKS Custom multi-lateral junctions Flow by access configurations ...

Single-trip 8-1/2″ whipstock-milling system was used to cut a window suitable for running drilling BHAs, liner, and completion equipment. The 9-5/8″ × 13-3/8″ annulus was monitored during ...

Single-trip 8-1/2″ whipstock-milling system was used to cut a window suitable for running drilling BHAs, liner, and completion equipment. The 9-5/8″ × 13-3/8″ annulus was monitored during milling and FIT test to check for any pressure communications. For well control scenario, arrangements were made for connecting the annulus to the ...

Abstract. This patent describes a single-trip whipstock assembly for diverting a well bore for continued production. It comprises: a hydraulically set anchor; a whip attached to an upper end of the anchor; and means for running the whipstock assembly into the well bore; wherein the whipstock assembly is run into the well bore and set within the well bore in a single trip by setting the anchor ...

The AlphaST ® single-trip openhole cementing and sidetrack system enables you to cement, anchor the whipstock, and mill off formation—without the need to set cement plugs or wait on cement to cure. The system drives down sidetracking costs, eliminates the need for multiple trips in hole, and avoids costly cementing operations for a variety ...