CDL Pre-Trip Inspection Practice Test

- Connecticut

- District of Columbia

- Massachusetts

- Mississippi

- New Hampshire

- North Carolina

- North Dakota

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- West Virginia

The pre-trip inspection test is neither an endorsement test nor a written test … but it is an essential part of the commercial driver’s license testing process.

The pre-trip vehicle inspection test is basically a skills test that is designed to determine if a driver can identify which features and equipment on a test vehicle should be inspected before operating the vehicle.

The test can cover a wide variety of equipment located both inside and outside of a truck. For example, the test could cover hoses and belts, specific parts of the engine, oil level, mirrors and windshield and much more. We’ll discuss in more detail what is covered on the test later in this guide.

Right now, let’s proceed on and take a close look at the test itself and the testing process.

Test Overview

The purpose of the vehicle inspection test is to both determine if a vehicle is safe to operate and to determine if a driver knows how to ensure his or her vehicle is safe to operate.

During the vehicle inspection test, the driver is expected to explain or show their knowledge of the vehicle inspection process. That means the driver will have to walk around the vehicle and point to or touch each item and explain to the examiner what they are checking and why.

If you do not pass this test, any other endorsement tests that you have scheduled will be canceled.

Before you go to the DMV to this and other endorsement exams, you should visit your state’s DMV website and find the following:

Age requirement for taking the test – most states require applicants to be 18 years of age with a valid driver’s license. If the driver is going to be driving from state to state, most states require that they be 21 years of age with a valid driver’s license.

Identification documents that most be produced to prove your identity. Sample documents that acceptable often include a birth certificate and a valid driver’s license.

Fees that will be due before taking the test. Also, as part of this step, be sure to check what payment methods are accepted at the DMV office you will be visiting.

What’s on the Test?

You will be required to conduct both an internal and external inspection of the test vehicle.

That means on the internal inspection you will have to identify and check such things as: engine hoses, engine belts, oil pressure, coolant level, power steering fluid, mirrors and windshield, safety equipment, temperature gauge, air gauge and more.

On the external inspection you will need to identify and check such things as: steering box, hoses and linkage, air brakes, suspension, wheels, tires, doors, splash guards and more.

During the test, the driver will NOT have to crawl under the hood or under the vehicle. The brake lights, emergency flashers, turn signals, and horn must be checked and if any of these items do not work, the skills and road portions of the test process will immediately be postponed.

One more thing, when taking the inspection test you may be able to use the guides shown in your commercial driver’s license handbook but you cannot have any instructions or notes written on them.

Here are some sample questions that you will need to be able to answer when conducting the pre-trip inspection:

- How much play is allowed in engine compartment belts?

- What might puddles on the ground or dripping fluids on the underside of the engine and transmission indicate?

- How should you go about checking the engine coolant level?

- When checking the wheels, what might rust around a nut indicate?

- How do you check the power steering fluid?

How to Prepare for the Test

We recommend a three step approach to preparing for this test.

Step One – study your commercial driver’s license handbook, paying particular attention to the pre-trip inspection section. Read this section multiple times and try to commit everything to memory.

Step Two – Take pre-trip inspection practice tests to asses and further increase your understanding of this topic. We offer pre-trip inspection practice tests right here .

Step Three – Take what you’ve learned and apply it to a real world truck. It’s one thing to see something in print but you should also look at a physical truck so that you know where essential components are and you can identify them.

Test Taking Tips – Improve Your Chances to Pass

Things you can do to improve your chances of passing this test include getting a good night’s rest the night before the exam.

You should also eat well before the test. This will ensure your mind and body have fuel needed to successfully execute the inspection.

Still more things that you can do include taking some deep breaths to relax yourself before beginning the test. You should also be very familiar with where the DMV is located and how to get there. Then you should plan on leaving early so that you will have to compose yourself before the test and you won’t feel rushed and stressed when you begin.

We also recommend scheduling an appointment at the DMV to avoid any long wait that can make you feel tired and stressed and negatively impact your test performance.

The pre-trip inspection test is a very important test because failing to pass this test will prevent you from being able to move an take scheduled endorsement exams.

This is done for a reason – because being able to identify that a truck is safe to operate is something that is critical for drivers to know how to do. Failure to master this skill can put lives at risk on the roadways.

So don’t take this test for granted. Study the handbook, take practice tests and be sure to practice inspections on real trucks to further expand your knowledge. Do these things and you’ll pass this test with flying colors and be able to move on to receiving the endorsements you covet.

Class A Pre-Trip Inspection Study App

The CDL Pre-Trip Inspection can be the most daunting portion of the driving test. But, it's easy if you study.

Use this FREE study guide to prepare for your CDL Skills test.

Would you like a video version of the Pre-Trip Inspection? Scroll to the bottom of this page for a free video.

Courtesy of CDL College .

Metal Parts: cannot be broken or cracked and must be securely mounted. Rubber Parts: no abrasions, bulges, or cuts. Parts that hold a Fluid or Air: cannot be leaking. Example: the engine air compressor (a metal part) is securely mounted, not cracked, gear-driven, and has no audible leaks.

• The Pre-Trip Inspection is a verbal test. • Say at least 2 things about every item you inspect. • Point to, or touch, every item that you inspect. • Mention all damaged items to the tester.

01: Engine Compartment + 1 Axle

Stand in front of the truck.

(3 L’s) Lights, Leans, Leaks

Verify that the LIGHTS on the front of the truck are the proper color, securely mounted, not cracked or broken, and clean.

Next, make sure the truck isn’t LEANing to one side, which could indicate a suspension problem or low tire pressure.

Ensure there are no LEAKS underneath the engine compartment.

Check the front of truck for damage. When you find damage on the vehicle, tell the tester that you’ll note it on your Vehicle Inspection Report.

3 Components

Alternator: securely mounted, not cracked; wires are properly fastened and not frayed. Belt or gear driven: If belt-driven, belt has no more than 1/2" to 3/4" of play, and no cuts or splits.

Water Pump: (see box on right) properly mounted and not broken; no visible leaks; belt or gear driven: belt has no more than 1/2" to 3/4" inch of play and no splits or cuts.

Air Compressor: securely mounted to engine, not broken or cracked; no audible leaks; belt or gear driven: belt has no more than 1/2" to 3/4" inch of play and no splits or cuts.

Coolant: verify proper level through sight glass or dipstick; reservoir is properly mounted not cracked; check the hoses for splits or cuts and ensure they are securely mounted at both ends.

Oil: indicate where the dipstick is located and that the oil is at the proper level.

Power Steering: verify proper level through sight glass or dipstick; reservoir is securely mounted and not cracked; check the hoses for splits or cuts and ensure they are securely mounted at both ends.

Belts and Hoses

After properly inspecting the power steering hose and the coolant hose , tell the tester that you would inspect all remaining hoses the same way. After properly inspecting the alternator belt , tell the tester that you will inspect all remaining belts the same way.

Steering Shaft: not bent or broken and securely mounted; no excessive play. Steering Gear Box: properly mounted to frame and not cracked or broken; no visible leaks; HOSE has no visible leaks and is properly mounted at both ends.

Pitman Arm: not cracked and securely mounted, all hardware is present. Castle nuts and cotter pins are present and tight. Drag Link: not broken and properly mounted at both ends. Rubber bushings: not split or cut and properly greased. Upper/Lower Control Arms and Tie Rod: not broken and securely mounted, all hardware present.

Spring Mounts: spring mounts and hardware are not cracked or broken and properly mounted to frame. Leaf Springs: not cracked or broken, not shifted or scissored; properly mounted to spring hangers. U-bolts: not cracked or broken and securely mounted.

Shock Absorber: not bent or broken and mounted securely; no visible leaks; rubber bushings have no dry-rot.

Brake Hose: hose to brake chamber not split or cut, no audible leaks, and securely mounted at both ends. Brake Chamber: not cracked or broken and securely mounted; no audible leaks. Slack Adjuster: no missing hardware and properly mounted; push rod has no more than 1" of play and is at a 90° angle to brake chamber. Brake Drum: securely mounted and not broken, no bluing from excessive heat. Brake Pads: securely mounted and not broken; minimum brake pad thickness is 1/4".

Wheel inside: not broken and securely mounted; no welding repairs. Tire: sidewalls have no cuts or bulges; steer tire tread depth is 4/32" min.; tread is evenly worn; check inflation w/ air gauge (do not kick tires) ; no re-treads on steers. Wheel outside: securely mounted and not cracked, no illegal welds. Valve Stem: properly secured and not broken; no audible leaks, has a metal cap. Lug Nuts: not cracked or broken; all lug nuts are present and tight. Hub Seal: not cracked, broken, or loose; no visible leaks. End this portion of the inspection at the Hub Seal.

02: Side and Back of Truck + 1 Axle

Side and back of truck.

Mirror bracket: properly attached to truck and not broken, all hardware in place. Door: securely mounted and opens and closes; hinges not broken and securely mounted; rubber seal not split or cut and is properly mounted. Steps: hold my weight, not loose, no debris. Fuel tank: not leaking and no loose hardware; cap is tight, seal intact and chain present. Exhaust: not loose, all hardware present, no evidence of leaks (exterior soot). Cat Walk and Steps: properly mounted and not excessively dirty. Frame: not twisted or broken and no illegal welds. Drive Shaft: not cracked or broken, U-joints not broken and have no foreign objects. Rear truck lights: proper color, all lights are present, not cracked or dirty, no moisture inside the lens. Mud Flap: bracket is securely mounted and not cracked, all hardware in place; mud flap not split or cut. DOT tape is securely mounted, not dirty, covers 100% of rear. Space: enough space between rear of truck and landing gear for turns.

Note: axle suspension components can be different from truck to truck. You should determine which suspension components are present and inspect those components. Axles consist of suspension, brakes, wheels, and tires. Spring mounts: spring mounts and hardware are not cracked or broken and properly mounted to frame. Leaf Springs: not cracked or broken, not shifted or scissored; properly mounted to spring hangers. U-bolts: not cracked or broken and securely mounted. Shock Absorber: not bent or broken and mounted securely; no visible leaks; rubber bushings have no dry-rot. Air Bags: not split or cut, no audible leaks; mounts are properly secured and not cracked. Brake Hose: hose to brake chamber not split or cut, no audible leaks, securely mounted at both ends. Brake Chamber: not cracked or broken and securely mounted; no audible leaks. Slack Adjuster: no missing hardware and properly mounted; push rod has no more than 1" of play and is at a 90° angle to brake chamber. Brake Drum: securely mounted and not broken, no bluing from excessive heat. Brake Pads: securely mounted and not broken; minimum brake pad thickness is 1/4". Wheel inside: not broken and securely mounted; no welding repairs. Tires: sidewalls have no cuts or bulges; tread depth on drive tires is 2/32" min.; evenly worn; check inflation w/ air gauge (do not kick tires) ; can be re-treads; Dual Tires: no foreign objects between tires, no gap between wheels. Wheel Outside: not cracked, securely mounted, no welding repairs. Valve Stem: properly secured and not broken; no audible leaks, has a metal cap. Lug Nuts: not cracked or broken; all lug nuts are present and tight. Hub Seal: not cracked, broken, or loose; no visible leaks. End this inspection at the Hub Seal.

03: Connections

Locate the air lines and the electrical line at the rear of the cab.

Air Lines should be securely mounted at BOTH ends. All hardware is present, nothing broken. Lines have no cuts or splits and no audible leaks. Glad hands are locked in place, not broken, and seals are not split or cut.

Electrical line is securely mounted at BOTH ends. All hardware is present and tight. Lines have no cuts or splits. Safety latches are in place. Lines are not tangled or dragging on catwalk.

Fifth Wheel Assembly: Apron: securely mounted, not cracked or broken. No gap between apron and skid plate. Skid Plate: properly greased, securely mounted, not cracked. Pivot pin is securely mounted, not cracked or broken. Platform: is securely mounted to frame and not cracked or broken. Release Handle: securely mounted, not broken and in locked position. Sliding Fifth Wheel? The actuator is not cracked or broken; air line is securely mounted, no audible leaks, no cuts or splits).

Kingpin and Locking Jaws: securely mounted and not worn. Locking jaws are secure around kingpin, both are properly greased.

04: Trailer + 1 Axle

Start at the front of the trailer, then inspect the side and the back. Finish with a trailer axle. Front of Trailer: clearance lights are the proper color, not loose, cracked, or dirty, and clean. Front of trailer has no holes, all rivets present. Side of Trailer: no holes in side of trailer, all rivets in place. DOT tape: properly secured, not dirty, covers at least 50% of the side. Frame: not twisted or broken, all hardware present and tight. Cross members: securely mounted, not loose or broken, none missing. Floor: securely mounted and no holes. Landing gear: is raised, not broken, securely mounted; Handle not broken, securely mounted, and operational. Clearance light: proper color, not loose, cracked or dirty; rubber gasket not split or cut. Air lines: are securely mounted under trailer, no audible leaks, not dragging on the ground. Tandem slide: not bent, properly mounted, pins locked in place. Release arm: securely mounted, not broken, and in locked position. Mud flap: securely mounted, no cuts, and proper distance from tire and ground. ABS light: not cracked or dirty, proper color, no moisture inside

Back of Trailer: clearance lights are the proper color, not cracked or dirty, and clean. Hinges: are securely mounted, bot cracked or broken. Doors: not broken, no holes; door seal intact, no cuts, securely mounted. Door handles and rods: are not bent, are securely mounted, and operational. Lights: proper color, securely mounted, not loose, cracked or dirty. DOT tape: is securely mounted, clean, and covers 100% of rear. Bumper: is properly secured, not cracked or broken.

Trailer Axle

Note: axle suspension components can be different from truck to truck. You should determine which suspension components are present and inspect those components. Axles consist of suspension, brakes, wheels, and tires.

Trailing Arm Mount: securely mounted to frame, not broken or cracked. Spring mounts: spring mounts and hardware are not cracked or broken and properly mounted to frame. Leaf Springs: not cracked or broken, not shifted or scissored; properly mounted to spring hangers. U-bolts: not cracked or broken and securely mounted. Shock Absorber: not bent or broken and mounted securely; no visible leaks; rubber bushings have no dry-rot. Air Bags: not split or cut, no audible leaks; mounts are properly securedand not cracked. Brake Hose: hose to brake chamber not split or cut, no audible leaks, securely mounted at both ends. Brake Chamber: not cracked or broken and securely mounted; no audible leaks. Slack Adjuster: no missing hardware and properly mounted; push rod has no more than 1" of play and is at a 90° angle to brake chamber. Brake Drum: securely mounted and not broken, no bluing from excessive heat. Brake Pads: securely mounted and not broken; minimum brake pad thickness is 1/4". Wheel inside: not broken and securely mounted; no welding repairs. Tires: sidewalls have no cuts or bulges; tread depth on drive tires is 2/32" min.; evenly worn; check inflation w/ air gauge (do not kick tires) ; can be re-treads; Dual Tires: no foreign objects between tires, no gap between wheels. Wheel Outside: not cracked, securely mounted, no welding repairs. Valve Stem: properly secured and not broken; no audible leaks, has a metal cap. Lug Nuts: not cracked or broken; all lug nuts are present and tight. Hub Seal: not cracked, broken, or loose; no visible leaks. End this inspection at the Hub Seal.

05: External Light Check

Follow the flow to avoid missing any lights: 4 sides for the truck, 4 sides for the trailer.

Group similar lights together (headlights and high beams; turn signals and 4-way flashers; brake lights and tail lights).

TRUCK LIGHTS

Front: clearance lights, headlights, high beams, left turn, right turn, 4-way flashers

Left side: clearance light, left turn, 4-way flasher

Rear: tail lights, brake lights, left turn, right turn, 4-way flashers

Right side: clearance light, right turn,4-way flasher

TRAILER LIGHTS

Front: clearance lights

Rear: clearance lights, tail lights, brake lights, left turn, right turn, 4-way flashers

Right side: clearance light, right turn, 4-way flasher

06: In Cab and Brake Test

Memorize this formula: 5, 5, Safe Start, 5, 5 5 safety items 5 in cab items Safe Start 5 gauges 5 -step brake check

5 Safety Items

5 in cab items.

Follow the blue spiral shape below to remember the 5 in cab items. Mirrors: glass not dirty or cracked, no illegal stickers, mirrors properly adjusted. Windshield: securely mounted, not dirty or cracked, no illegal stickers. Windshield wipers: arms properly mounted and not broken; blades have no splits or cuts, wipers and wiper fluid are operational. Heater/defroster: demonstrate both are operational by setting fan to max, and the mix valve to heat/defrost. Dashboard light indicators: turn the lights on and check the indicators for the high beams, right and left turn signals, and 4-way flashers.

Tell the examiner these 3 steps before you perform them: parking brake is set, transmission in neutral, and the clutch is depressed. Start the engine and look for the ABS light on the dash to come on and then go off. With the vehicle started, check the gauges.

Oil gauge: operational, rising to proper operating range, no warning light. Temperature gauge: operational, rising to proper operating range, no warning light. Voltmeter: operational, at the proper operating range, 12-14 volts. Air gauges (2): building air to proper operating range, no warning lights.

5-step Brake Test

Explain each step before performing it. With the first 2 steps, you’re either trying to move the vehicle, or you are moving the vehicle. The engine must be ON for the first 2 steps. 1) Parking Brake: release trailer brake (push RED valve IN); slowly release the clutch, tugging lightly against the parking brake. Push clutch in. (Leave everything in the truck as it is). 2) Service Brake: (brake pedal) release parking brake (BOTH valves should be IN), pull forward to 5 mph, depress clutch and brake while lightly gripping the steering wheel; check if vehicle pulls to the left or right. (Leave everything in the truck as it is).

**Turn the engine OFF, and turn the key ON for the next 2 steps. You’ll need power for your gauges.**

Air Compressor check: perform a Safe Start. Idle up the engine (1200RPM) until the secondary air tank reads 85psi. At 85psi begin counting. The air pressure must rise from 85 to 100psi in 45 seconds or less. Next, fast idle the truck up to 120-140psi, at which point the governor cut-out should occur. Psshhh!

Class A CDL Pre-Trip Inspection Video

Want the youtube version of the Class A Pre-Trip Inspection video? Watch the youtube version.

Would you like our help finding a CDL driving job?

Try our version of a job board- Gary's Job Board. CDL Job Board Receive daily job offers in your email for FREE. Sign up takes 2 minutes. Review Gary’s jobs. Reply to the jobs you like, trash the crappy ones. Gary puts drivers in control.

Visit CDL College for all of your truck driving school needs .

Class A Pre-Trip Inspection Study App Copyright© 2018 CDL College

CDL Pretrip Test

Boost your confidence: the essential cdl pretrip practice test prep, cdl pretrip practice test: essential tips for passing your exam, understanding the importance of cdl pretrip practice test.

At the onset of your journey to becoming a commercial driver, it is vital to comprehend the significance of the CDL pretrip practice test. This evaluation is designed to assess your ability to inspect a vehicle for safety and operational issues, as well as to ensure you are familiar with the components of a commercial vehicle.

Familiarizing Yourself with the Inspection Requirements

Before embarking on the CDL pretrip practice test, it is imperative to acquaint yourself with the inspection requirements mandated by the Department of Transportation (DOT). Familiarize yourself with the various components of a commercial vehicle, including the engine compartment, coupling systems, brake systems, and more.

Effective Strategies for Acing the CDL Pretrip Practice Test

- Consistent Practice Regular practice is paramount to success in the CDL pretrip practice test. Devote time to conducting thorough inspections of commercial vehicles, ensuring you are well-versed in identifying potential safety hazards and mechanical issues.

- Utilize Study Materials Leverage study materials such as manuals, online resources, and practice test questions to reinforce your understanding of commercial vehicle components and inspection procedures.

- Seek Guidance Seek guidance from experienced commercial drivers or instructors to gain valuable insights and tips for acing the pretrip practice test. Their practical knowledge and advice can significantly enhance your preparedness.

Embracing the Opportunity for Growth

Approach the CDL pretrip practice test as an opportunity for personal and professional growth. Embrace the challenge and commit to honing your skills in vehicle inspection, as this will not only bolster your chances of passing the test but also contribute to your overall competence as a commercial driver.

By embracing a proactive approach to mastering the CDL pretrip practice test, you can instill confidence in your abilities and pave the way for a successful career in commercial driving. Remember, preparation and diligence are key to conquering this pivotal assessment.

In conclusion, the CDL pretrip practice test serves as a fundamental evaluation of your ability to conduct thorough vehicle inspections, thus emphasizing the importance of meticulous preparation and dedication to mastering commercial vehicle components and inspection procedures. As you embark on this journey, equip yourself with the knowledge and commitment required to excel in the test and lay a solid foundation for a flourishing career in commercial driving.

- Free Practice Tests

Commercial Driving

- Introduction

- Getting a CDL

- Fees and costs

- CDL Types & Permits

- Endorsements & Restrictions

- Written exams

- Skills test

- Pre-trip inspection

- TSA background check

- Retake policy

- CDL Maintenance

- ELDT Training & Certification

- CDL how-to guides

Mastering the CDL Pre-Trip Inspection Exam: A Complete Guide

Learn how to conduct thorough pre-trip inspections with our guide, a critical component for commercial vehicle safety.

Written by Andrei Zakhareuski. With over 16 years of expertise, Andrei leads Driving-Tests.org, a top online resource for driver education. His leadership has established vital partnerships with over 2,600 libraries, educational bodies, and state agencies.

The CDL Pre-Trip Inspection Exam is an integral part of obtaining your commercial driver’s license. This guide covers Class A and Class B pre-trip inspections, provides a checklist, and offers tips for memorizing the inspection process.

Start a free Pre-Trip Inspection practice test:

- Alabama - AL - Alabama Pre-Trip Inspection Practice Test

- Alaska - AK - Alaska Pre-Trip Inspection Practice Test

- Arizona - AZ - Arizona Pre-Trip Inspection Practice Test

- Arkansas - AR - Arkansas Pre-Trip Inspection Practice Test

- California - CA - California Pre-Trip Inspection Practice Test

- Colorado - CO - Colorado Pre-Trip Inspection Practice Test

- Connecticut - CT - Connecticut Pre-Trip Inspection Practice Test

- Delaware - DE - Delaware Pre-Trip Inspection Practice Test

- District of Columbia - DC - District of Columbia Pre-Trip Inspection Practice Test

- Florida - FL - Florida Pre-Trip Inspection Practice Test

- Georgia - GA - Georgia Pre-Trip Inspection Practice Test

- Hawaii - HI - Hawaii Pre-Trip Inspection Practice Test

- Idaho - ID - Idaho Pre-Trip Inspection Practice Test

- Illinois - IL - Illinois Pre-Trip Inspection Practice Test

- Indiana - IN - Indiana Pre-Trip Inspection Practice Test

- Iowa - IA - Iowa Pre-Trip Inspection Practice Test

- Kansas - KS - Kansas Pre-Trip Inspection Practice Test

- Kentucky - KY - Kentucky Pre-Trip Inspection Practice Test

- Louisiana - LA - Louisiana Pre-Trip Inspection Practice Test

- Maine - ME - Maine Pre-Trip Inspection Practice Test

- Maryland - MD - Maryland Pre-Trip Inspection Practice Test

- Massachusetts - MA - Massachusetts Pre-Trip Inspection Practice Test

- Michigan - MI - Michigan Pre-Trip Inspection Practice Test

- Minnesota - MN - Minnesota Pre-Trip Inspection Practice Test

- Mississippi - MS - Mississippi Pre-Trip Inspection Practice Test

- Missouri - MO - Missouri Pre-Trip Inspection Practice Test

- Montana - MT - Montana Pre-Trip Inspection Practice Test

- Nebraska - NE - Nebraska Pre-Trip Inspection Practice Test

- Nevada - NV - Nevada Pre-Trip Inspection Practice Test

- New Hampshire - NH - New Hampshire Pre-Trip Inspection Practice Test

- New Jersey - NJ - New Jersey Pre-Trip Inspection Practice Test

- New Mexico - NM - New Mexico Pre-Trip Inspection Practice Test

- New York - NY - New York Pre-Trip Inspection Practice Test

- North Carolina - NC - North Carolina Pre-Trip Inspection Practice Test

- North Dakota - ND - North Dakota Pre-Trip Inspection Practice Test

- Ohio - OH - Ohio Pre-Trip Inspection Practice Test

- Oklahoma - OK - Oklahoma Pre-Trip Inspection Practice Test

- Oregon - OR - Oregon Pre-Trip Inspection Practice Test

- Pennsylvania - PA - Pennsylvania Pre-Trip Inspection Practice Test

- Rhode Island - RI - Rhode Island Pre-Trip Inspection Practice Test

- South Carolina - SC - South Carolina Pre-Trip Inspection Practice Test

- South Dakota - SD - South Dakota Pre-Trip Inspection Practice Test

- Tennessee - TN - Tennessee Pre-Trip Inspection Practice Test

- Texas - TX - Texas Pre-Trip Inspection Practice Test

- Utah - UT - Utah Pre-Trip Inspection Practice Test

- Vermont - VT - Vermont Pre-Trip Inspection Practice Test

- Virginia - VA - Virginia Pre-Trip Inspection Practice Test

- Washington - WA - Washington Pre-Trip Inspection Practice Test

- West Virginia - WV - West Virginia Pre-Trip Inspection Practice Test

- Wisconsin - WI - Wisconsin Pre-Trip Inspection Practice Test

- Wyoming - WY - Wyoming Pre-Trip Inspection Practice Test

CDL Class A Pre-Trip Inspection

Engine Compartment Inspection

Includes checking for leaks, belt tension, and the condition of hoses, among other components.

Cab Check/Engine Start

Involves inspecting the cab’s interior, gauges, and starting the engine to check for abnormalities.

Brake Check

Focuses on air brake systems, including air brake checks and the parking brake test.

CDL Class B Pre-Trip Inspection

Vehicle Overview

Begin with a general overview of the vehicle, checking for obvious signs of damage or issues.

External Inspection

Inspect all external components, including tires, lights, and mirrors.

Internal Inspection

Check all internal controls, ensuring everything is functional and within reach.

Pre-Trip Inspection Checklist

- Lights and reflector s: Ensure all are clean and functional.

- Engine oil and coolant levels : Check for adequate levels.

- Steering mechanism : Ensure it’s secure and functioning.

- Horn : Test for functionality.

- Windshield wipers : Check for operability and condition.

- Mirror s: Adjust for optimal visibility.

- Emergency equipment : Ensure presence and accessibility.

- Air brake system : Test for leaks and proper pressure.

Tips for Memorizing the Pre-Trip Inspection for CDL

- Create a Routine : Develop a consistent order in which to conduct your inspection.

- Use Mnemonics : Create acronyms or phrases to help remember the steps.

- Practice Regularly : Hands-on practice is the most effective way to memorize the inspection process.

- Visual Aids : Use diagrams or checklists as visual reminders.

Pro Tip : Practice the pre-trip inspection in a real-world setting. The more you perform the inspection in a practical environment, the more natural it will become.

Remember, the pre-trip inspection is not just a test requirement – it’s a fundamental safety practice every commercial driver should master. For more resources and detailed guides, visit Driving-Tests.org .

Secure your CDL with confidence!

Our exclusive CDL Premium program offers comprehensive online training with an ELDT certificate, authentic exam questions, and a solid Pass Guarantee, starting at only $69. Ideal for first-time applicants, seasoned drivers, and those new to the U.S. road rules.

Explore CDL Premium

Was this page helpful?

- Start a free Pre-Trip Inspection practice test:

- CDL Class A Pre-Trip Inspection

- CDL Class B Pre-Trip Inspection

- Pre-Trip Inspection Checklist

- Tips for Memorizing the Pre-Trip Inspection for CDL

CDL Pre-Trip Inspection Checklist

Studying this Class-A CDL pre-trip inspection checklist is an important part of truck driver training. Before getting your Class-A CDL and finding an entry level truck driving job , most states will require students to pass a DOT (department of transportation) pre-trip inspection test and a general knowledge test .

Each company’s pre-trip inspection varies slightly. Most likely you will have to do the coupling system, light check and in-cab inspections plus one of the remaining three sections.

Pre Trip Inspection Checklist

Download free and print it! Printable Pre Trip Inspection Checklist (PDF)

There are many sections to learn but the test is not as difficult as it may seem. Studying our simplified Class-A pre-trip inspection checklist and taking classes at your local CDL training school will get you prepared.

Engine Compartment

Driver door fuel area, coupling area, light check, in-cab inspection and brake tests, belt driven alternator, belt driven water pump, brake chamber, brake lining, caste nuts and cotter pins, coolant reservoir, gear box and hoses, gear driven air compressor, gear driven power steering pump.

- General Hoses

Leaf Springs

Power steering fluid reservoir, shock absorber, slack adjuster and push rod, spring hanger, steering column, what to check for:.

When checking the engine compartment, you will always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent or broken. The items you will need to check for include:

- Make sure all of the wires are connected. The belt should not be cracked or frayed and the free play on the belt should be between ½ to ¾ of an inch.

- The free play on the belt should be between ½ to ¾ of an inch. Also check all the hoses running to and from the water pump to make sure nothing is leaking.

- The brake chamber should not be leaking air.

- The brake drum should be properly mounted and secure.

- The brake hose is rubber, so it is important to make sure it is not leaking air.

- Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

- Make sure all three caste nuts and cotter pins are present.

- The reservoir should not leaking and must be filled to the manufacturer’s specifications.

- Make sure the drag link is properly mounted and secure, and not cracked, bent or broken.

- The gear box and hoses should have no abrasions, bulges or cuts, and should not be leaking.

- Although the air compressor is hard to see, you must make sure it is properly mounted and does not leak.

- The steering pump is located in the same place as the air compressor and is also gear driven. Ensure the steering pump is not leaking.

General Hoses (Passenger and Driver’s Side)

- The hoses should be secure at both ends. There should be no abrasions, bulges or cuts. Fluids run through these hoses, so it is important to make sure they are not leaking.

- The hub seal (or axle seal) should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure none of the leaf springs have shifted.

- Check for leaks under the truck.

- There should be no lug nuts missing. Look for rust trails, powder residue and cracks around the bolt holes.

- The oil level should be filled to the manufacturer’s specifications.

- Make sure the pitman arm is properly mounted and secure. It should be not cracked, bent or broken.

- Make sure this reservoir is not leaking and filled to the manufacturer’s specifications.

- The rim cannot have any unauthorized welds.

- Make sure the shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

- With the brakes released and pulled by hand, the push rod should never move more than one inch.

- The spring hanger should be properly mounted and secure.

- Make sure the steering column is properly mounted and secure. It should not be cracked, bent or broken.

- Look for abrasions, bulges or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires must be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- Make sure the tie rod is properly mounted and secure, not cracked, bent or broken.

- Make sure all are accounted for.

Back to top of Engine Compartment

Catwalk and Steps

Door and hinges, drive shaft, exhaust system, frame and cross members, spring mount.

Again it is important to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

- The actual airbag is rubber, so it is important to check for abrasions, bulges, cuts and leaks, in addition to any missing mounting bolts.

- The axle seal should not be leaking and should be filled to the manufacturer’s specifications.

- Make sure to mention the brake chamber is not leaking air.

- Make sure the brake drum is secured properly. Also look for cracks, bends and breaks.

- Check the brake hose at both ends to make sure it is not leaking air.

- There should be no oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- The cat walk and steps should be clear of any loose objects.

- Physically demonstrate that the doors open, close and latch properly. Door seals should not be worn, torn or rotten.

- The drive shaft should not be twisted and the u-joints should be free of any debris.

- The tread and sidewalls should have no abrasions, bulges or cuts. The tread depth should be no less than 2/32 of an inch. Tires should be properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

- The exhaust system should show no signs of leaks.

- There should be no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

- Fuel should not be leaking from the tank and the cap should always be on tight.

- Rust trails could indicate loose bolts, while powder residue and racks around the bolts could mean the bolts have been over-tightened.

- Mirrors should be clean for best visibility.

- Make sure the mud flap is secured properly. Also look for cracks, bends and breaks.

- Make sure to mention there should be never be any unauthorized welds.

- The shock absorber should be secure at both ends and not leaking. If it does leak, it will leak in the middle.

- With the brakes released and pulled by hand, the push rod should not move more than one inch.

- If you are equipped with duals, check to see there is proper spacing between the tires and there is nothing stuck.

- The spring arm should be secure at both ends.

- The spring mount should be secure at both ends.

- Make sure the torque arm is secured properly. Also look for cracks, bends and breaks.

- Make sure to check and mention that no U-bolts are missing.

Back to top of Driver Door Fuel Area

Electric Line

Locking jaws, mounting bolts, release arm, sliding fifth wheel locking pin.

- Air lines should be secure at both ends with no abrasions, bulges or cuts. They should not be leaking, dragging or tangled.

- Make sure the apron is properly mounted and secure. Look for cracks, bends and breaks.

- Make sure there is enough space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

- The electric line should be secure at both ends. There should be no abrasions, bulges, cuts or exposed wires.

- The gap is not an actual item, however there should be no space between the apron and the skid plate.

- The seals should be in good condition with no cracks, signs of rotting, or leaking air.

- Make sure the king pin is properly mounted and secure. Look for cracks, bends and breaks.

- You must physically check that the locking jaws is fully locked around the king pin.

- No mounting bolts should be missing.

- Make sure the platform is properly mounted and secure. Look for cracks, bends and breaks.

- The release arm should be in the fully locked position.

- The skid plate needs to be properly lubed.

- The pin must be in the fully locked position.

Back to top of Coupling Area

Header Board

Landing gear, rear door and hinges.

- Shock Absorbers

Tandem Frame and Release

Trailer tire.

- Again make sure the airbag has no abrasions, bulges, cuts or leakings. The airbag should not be missing any mounting bolts.

- The brake chamber should be properly mounted so that is does not leak air.

- The brake hose should be secure at both ends with no abrasions, bulges, cuts or leaks.

- Check for oil or debris on the brake lining. There should be at least ¼ of an inch of friction material.

- There cannot be any missing cross members.

- The header board cannot have any holes or missing rivets.

- The landing gear must be fully raised and the cradle handle secure.

- Rust trails indicate loose bolts. Powder residue and cracks around the bolt holes could be an indication of over-tightened bolts.

- The rims cannot have any unauthorized welds.

- The rear door should open, close and latch properly. Door seals should not be worn, torn or dry rotten.

- The shock absorber should be checked at both ends for leaks.

- When the brakes are released and pulled by hand, the push rod should not move more than one inch.

- Release handle and locking pins should be in the fully locked position.

There should be no abrasions, bulges or cuts to the tread or sidewalls. Tread depth should be no less than 2/32 of an inch. The tire should be properly filled to manufacturer’s specifications and checked with an air gauge.

- Front of the truck

- Both sides of the truck

- Rear of the truck

- Both sides of the trailer

- Rear of the trailer

Back to top of Trailer

The five functions are:

- Left turn signal

- Right turn signal

- Four way flashers

- High/low beams

- Brake lights

Back to top of Light Check

- Airbrake Test

Air Pressure Gauges

Emergency equipment, heater and defroster, lighting indicators, oil pressure gauge, parking brake, service brake check, water temperature gauge, windshield and mirrors, windshield wipers and washers.

The last section is In-Cab Inspection and Brake Tests. For the In-Cab Inspection you will once again want to make sure all of the following components are properly mounted and secure. As well as the following:

Air Brake Test

There are three stages to an air brake test:

- Applied Pressure Test – When doing the Applied Pressure Test, you will want to build the air pressure to governor cut out. Put the truck in the lowest gear, turn the engine off and immediately turn it back on. Push in the tractor and trailer valves which will then release the parking brakes. Push and hold the brake pedal, allowing the gauges to stabilize. When the gauges have stabilized, announce the Primary and Secondary PSI. Listen for air leaks while doing this.

- Warning Light and Buzzer – Pump down on the brake pedal until the warning light and buzzer comes on. This is typically at or before 60 PSI.

- Tractor/Trailer Protection Valve Pop Out – Pump down on the brake pedal until the tractor and trailer protection valves pop out, this will be between 20 and 40 PSI.

- The air pressure gauges should build to governor cut out.

- Your truck should have a fire extinguisher, three red reflective triangles and spare electrical fuses.

- Demonstrate both the heater and defroster are working properly.

Horns (Air Horn and City Horn)

- Blow both horns to make sure they are working.

- Check the left turn, right turn, four way flashers and high beams; also point these out on the dashboard.

- Make sure transmission is in neutral and then fully depress the clutch. Turn the key on, check the ABS light, announce when it comes on and off, and start the engine.

- The seat belt should not be ripped or frayed and should adjust and latch properly.

- The engine oil pressure gauge should rise to normal operating range.

- Trailer Parking Brakes – Set the trailer brake, release the tractor brake, then tug lightly on the trailer.

- Tractor Parking Brakes – Set the tractor brake, release the trailer brake and tug lightly on the trailer.

- Release both the tractor and trailer brakes. Drive at idle speed. Apply the service brake to make sure you come to a complete stop and that it doesn’t pull to the left or right when applying the brakes.

- The voltmeter should be charging between 13 and 14 volts.

- The water temperature gauge should also rise to normal operating range.

- The windshield and mirrors must be clean, with no obstructions and in proper adjustment.

- Demonstrate the wipers and washers are working properly by spraying the windshield.

Back to top of In-Cab Inspection and Brake Tests

During a CDL pre-trip inspection, truckers inspect many aspects of their commercial vehicle, including the overall safety of the vehicle; major hoses, fluid levels, and vehicle belts; the clutch or gear shift; and emergency equipment. The driver demonstrates their knowledge by walking around the vehicle, checking various safety components and explaining why each part should be checked for safety.

Reference and practice tests:

- Printable Pre Trip Inspection Checklist (PDF)

- CDL General Knowledge Practice Test

- Pre Trip Inspection Practice Test

- CDL HAZMAT Endorsement Practice Test

Edited for 2024 on 12/5/23

CDL Pre-Trip Inspection Test 1 – Practice Mode

Pre-Trip Inspection Test #1 is based on State CDL Manual Section 11.1.1 Engine Compartment (Engine Off)

See below for more information or go to our CDL Pre-Trip Inspection Learning Center .

Note: Pre-Trip tests do not have CDL manual reference after each question like our other testing areas. Instead, the whole CDL section that applies to the test can be found at the bottom of each test page for your reference.

Take this same test in our other testing modes …

Classic Mode | Exam Mode

Official State CDL Manual Section 11.1.1 Engine Compartment (Engine Off)

Leaks/Hoses

- Look for puddles on the ground.

- Look for dripping fluids on underside of engine and transmission.

- Inspect hoses for condition and leaks.

- Indicate where dipstick is located.

- See that oil level is within safe operating range.

- Level must be above refill mark.

Coolant Level

- Inspect reservoir sight glass, or

- Remove radiator cap (if engine is not hot), and check for visible coolant level.

Power Steering Fluid

- Indicate where power steering fluid dipstick is located.

- Check for adequate power steering fluid level.

Engine Compartment Belts

- Power steering belt.

- Water pump belt.

- Alternator belt.

- Air compressor belt.

Note: If any of the components listed above are not belt driven, you must:

- Tell the examiner which component(s) are not belt driven.

- Make sure component(s) are operating properly, are not damaged or leaking, and are mounted securely.

- CDL Exam Simulator

- OR Pretrip CDL Exam Simulator - 2

FREE 2024 Oregon (OR) Pretrip Exam Simulator 2

2024 or pretrip information.

The pretrip exam is an oral exam that you will need to pass after you have taken all of your CDL written tests, and are at the exam station for your pretrip, skills, and road test exams. During the pretip exam you will need to verbally check components to make sure that the vehicle is safe for operation. In some states there can be over 100 items to check on a tractor trailer.

The exam doesn’t stop at just listing the components, you will have to name the item by its proper name and say at least 3-5 things you would check that item for. Don’t’ forget to mention what you are going to check the 3-5 things for as well. This is a very detailed exam on the vehicle and its parts be ready.

As an example, the air compressor would need checked, we are going to check belts (if not gear driven), air lines, and securement of the air compressor. Because we mentioned belts (if not gear driven) we have to check for play in the belt, check it for wear, and crack. Moving on the air lines, need to be secure, no breaks or cracks, and no leaks. Finally check all bolts, nuts, and securement pieces to make sure none are loose or missing.

Based on the 2024 OR CDL Driver's Manual

Questions appearing on this cdl practice test:, after the engine compartment it is best to move to the driver's side of vehicle, and then head into the cab., at the side of the cab you should not check., the fuel and air tanks are checked for the same items except, steps leading into the vehicle should be, handrails should be checked for, is it best to check the seat and the seatbelts before sitting down, the first thing you should check or do when you sit in the driver's seat is, check your mirrors from the inside of the cab for, items inside the cab you must make function in order to get credit for them are, the steering wheel should be checked for, before you start the vehicle you should check, these are all gauges that will need checked except, the air pressure in a commercial vehicle should rise to governor cutout of, which gauge should be between 12-14, and in the green, what should the water temperature gauge do when you start the vehicle, you don't have to make both the air and city horns work to get credit for them., what interior lights do you need to check, what items are part of your safety equipment, to test the parking brake you should have the trailer air supply in, trailer hand break released, and the parking brake _____, testing the parking brake requires you to, to test the service brake test you will need to have the trailer air supply valve in, parking brake in, and the hand brake released. how do you test the service brake, the next step is the cdl air brake test. this portion is done with the engine off, but should you have air pressure built up to governor cut of 120-140, during the cdl air brakes tests the first step is to check for air leakage, to test air leakage the air valves should be, step 1 of the cdl air brake tests makes sure the leak rate of the red and blue line is not unsafe. with the parking brake released and the brake pedal applied the leak rate should be no more than, next you should fan the brakes down to make sure all air brake safety devices are working, but what should you do before starting to fan the brakes, while fanning down the alarm and light indicating low air pressure should come on at, fanning the brakes down further after the alarm and buzzer come on should result in the parking brake popping out for a single vehicle, and the parking brake and the trailer air supply popping out for a combination vehicle at, before you leave the inside can you should not check the exterior lights., exterior lights that need checked are on which side of the vehicle, what lights will you need to check on the exterior, more oregon cdl exam simulator: ( indicates current test), general knowledge exam simulator 1, general knowledge exam simulator 2, general knowledge exam simulator 3, general knowledge exam simulator 4, general knowledge exam simulator 5, general knowledge exam simulator 6, general knowledge exam simulator 7, general knowledge exam simulator 8, haz mat exam simulator 1, haz mat exam simulator 2, haz mat exam simulator 3, haz mat exam simulator 4, school bus exam simulator 1, school bus exam simulator 2, school bus exam simulator 3, school bus exam simulator 4, passenger vehicles exam simulator 1, passenger vehicles exam simulator 2, passenger vehicles exam simulator 3, passenger vehicles exam simulator 4, air brakes exam simulator 1, air brakes exam simulator 2, air brakes exam simulator 3, air brakes exam simulator 4, combination vehicles exam simulator 1, combination vehicles exam simulator 2, combination vehicles exam simulator 3, combination vehicles exam simulator 4, combination vehicles exam simulator 5, double/triple trailers exam simulator 1, double/triple trailers exam simulator 2, double/triple trailers exam simulator 3, tanker vehicles exam simulator 1, tanker vehicles exam simulator 2, tanker vehicles exam simulator 3, pre-trip inspection exam simulator 1, pre-trip inspection exam simulator 2, pre-trip inspection exam simulator 3, oregon free pretrip videos, engine compartment pretrip inspection, inside cab pretrip inspection, rear of tractor pretrip inspection, exterior light pretrip inspection, complete trailer pretrip inspection.

Complete pre-trip inspection checklist for truck drivers

By The Schneider Guy

Estimated reading time: 4 minutes

As a truck driver, performing a CDL pre-trip inspection is one of the most common and repeated tasks you will complete. Pre-trip inspections help truck drivers ensure their tractor and trailer are safe to operat e before hitting the road.

Keep reading to learn what a p re -trip inspection is and what should be on a p re -trip inspection checklist .

What is a pre-trip inspection?

A pre-trip inspection includes checking over the tractor and trailer a truck driver will be operating . A pre-trip should be completed before the operation of a vehicle :

- At the beginning of a driver’s shift.

- Any time a new trailer is picked up.

- After a 10-hour break.

A thorough inspection usually takes anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4) .

How to complete a CDL pre-trip inspection

CDL pre-trip inspection checklist

1. passenger-side engine: .

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbocharger: No oil or exhaust leaks.

- Engine air ductwork: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Secure m ounting .

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight .

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 4/32 min ( DOT ) .

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if it’s a sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks or missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secure mounting , no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked.

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 2/32 min ( DOT ) .

- Airbag (bellows): Fully inflated, secure mounting, not ruptured.

7. Side of cab:

- Mirrors: Secure m ounting , no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Secure m ounting , cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures the cap to the tank.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

- Electrical cord: No bare wire, no corrosion, check the plug at the end of the cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab airbag (bellows): Not ruptured, securely mounted.

9. Driveshaft/rear frame:

- Driveshaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds or missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line /glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light is working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ inch thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 2/32 , air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Secure m ounting , band clamp secure.

15. Gauges/inside the truck:

- Fuel: Matches visual when looking in the tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Please note that the list above is just an example. It is important to remember the type of driver you are, the company you work for and the type of truck you drive can impact your CDL pre-trip inspection . Be sure to consult your company guidelines or speak with your leader for more information on your post-trip inspection requirements.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."

Related posts

8 CDL Road Test tips to help you pass

How hard is it to get a CDL?

How to get your CDL – 7 simple steps for new truck drivers

NATIONAL TRAINING, INC.

DO I QUALIFY?

REQUEST INFO

MAKE A PAYMENT

800-488-7364

- Follow Follow

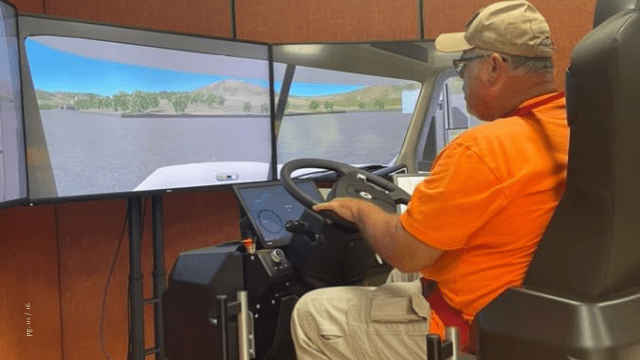

Get Into the Seat of Our State-of-the-Art Simulator System!

National Training Inc.’s state-of-the-art simulator system from Simulator Systems International provides a low-risk, low pressure way to train both new and experienced drivers. With bold realistic graphics, authentic and genuine truck components, and a 3 axis motion platform to offer an immersive experience, drivers and students are receiving a total immersive training solution, right at their fingertips.

Call us today to discuss further details of our CDL simulator training and learn how it can improve the success of your drivers, your fleet, and your company.

Where technology and training come together.

Whether you are looking for refresher training, continuing education, skills improvement, or student driver training, our simulator can provide measurable benefits to your drivers, your fleet, and your company’s bottom line. With realistic simulator training, you will enable safer, more efficient drivers who will protect your vehicle fleet with their optimal driving skills. Our simulators offer realistic driving practice equipment in a low-risk, controlled simulation environment to build confidence and develop efficient skills.

Immersive components to mimic real-life road conditions

Improved concept retention with hands-on interaction

Reduced accidents and measurable safety improvements

Introduction of industry advancements to both new and experienced drivers

Enabling of safer, more efficient drivers

Understandable behavior modification skills

Results-based immediate feedback and correctional guidance

"1 HOUR Simulator Training = 4 HOURS Behind-The-Wheel (BTW) Training"

– Schneider National

Trucking industry leader Schneider National has championed the use of simulators for almost 15 years. According to Don Osterberg , Senior Vice President – Safety & Security for Schneider, the company’s use of simulators since 2005 has helped reduce the carrier’s crash rates significantly. When compared with traditional training methods such as classroom work or in-cab instruction, simulator training methods reduced accidents by 32%.

Schneider believes that one hour of simulator time is equal to four hours of BTW training. When the extreme fuel costs for on-the-road training are taken into consideration, the result is a significant savings. And as fuel costs continue to increase, the positive impact to your bottom-line savings in fuel expenses alone will make your transition to simulator training well worth it.

FL CDL Manual

NEW! FL CDL Manual Supplement

Benefits of Using CDL Simulation Training

NTI’s simulators can be used for new driving students, 3rd party testers, and for trucking companies who wish to perform safety evaluations. Simulators are more advanced than ever before, and can mimic road surfaces, hazards, weather conditions, and other challenges that drivers may face in their everyday trucking experiences. By using our simulator as a fully integrated portion of a safe and effective training curriculum, drivers will gain experience in the low-risk setting of a completely controlled environment. When your drivers understand how to properly execute controls, manage shifting and braking, and drive properly, you will save money on costly maintenance and repairs. When training is conducted in a safe simulated environment, there will be no material damage, injury, or accidental incidents on the road. Young student drivers may not yet have a proper grasp on the ability of what it takes to drive a commercial truck and may make rash decisions, leading to costly mistakes or serious injury to themselves or others on the road. Simulator training eliminates the damage that can occur when inadequately trained drivers are given only behind-the-wheel or in-cab training.

New Drivers & 3rd Party Testers

Experienced drivers.

Gain exposure to real road conditions and build confidence levels

Become familiar with all operating controls, switches, and panel instruments

Experience rare but potentially catastrophic events and learn how to react

Receive immediate feedback and constructive guidance

Learn effectively from training mistakes and minimize their occurrence on the road

Learn and practice new skills and novel approaches

Be introduced to innovative equipment

Address a gap in skills efficacy or efficiency

Receive testing to ensure optimal safety skills

Our CDL Simulators Can Be Used For CDL Class A, B, and C Training Programs

All of the National Training Inc. programs are fully integrated to offer the most effective training with the best learning retention possible. We offer a combination of simulator training, hands-on CDL training, and behind-the-wheel training, to ensure that our training candidates are fully prepared for their new career.

Truck Driver CDL Class A Training Programs

Students can be effectively prepared to receive their CDL and begin a truck-driving career in as little as a month! In that short duration, we can train beginning students who have zero experience operating a big rig cab and prepare them with real-world training in the safety of our simulator environment.

This training program includes:

- Safe operation of a truck under normal driving conditions

- Introduction to and practice with all basic controls

- Combination of online simulator and hands-on CDL training to guide new drivers in all areas of their intended profession

- 122 hours of hands-on driving time behind the wheel of a Class A 18-wheeler truck

Truck Driver CDL Class B Training Programs

Over the five days and 40 hours of training that this CDL Class B program offers, drivers will be fully trained on what they need to begin their career as a Class B driver. The 40 included training hours consist of a combination of App+ Simulator (30 hours) and hands-on (10 hours) training models. Candidates for this program must hold a current Class E or C license, have their CDL permit, and have their DOT physical completed.

This training program includes:

- A combination of online simulator training and hands-on CDL training to improve skills and prepare drivers for every aspect of their profession

- 10 hours of hands-on driving time behind the wheel of a Class B Manual Box Truck

Truck Driver CDL Class C (Including Hazmat)

This course is the best option for fully licensed drivers that currently hold a CDL. National Training Inc. offers training courses in a variety of durations to meet the needs of drivers who would like to refresh their existing skills. These 1, 2, and 5 day CDL training programs are perfect for experienced drivers who would like to improve their skills in an existing area, or would like to be licensed for Hazardous Materials transportation. This refresher program is designed to complement the existing skills of drivers who currently hold a Class A, B, or C license.

- Customized CDL training to serve as a refresher course for experienced and currently licensed drivers

- Hazmat training for efficient and safe transport of hazardous materials

- Hands-on driving time behind the wheel of a semi tractor-trailer

Proficiency vs Hours

FMSCA has announced that driver proficiency will be given increased priority in CDL testing, as drivers will be expected to demonstrate a higher level of testable skills than ever before, along with superior command behind the wheel. Driving simulators can efficiently measure proficiency at the level expected by the FMSCA, and can progressively increase difficulty, track progress, and monitor results.

As the FMSCA commits to higher levels of safety and proficiency standards, drivers will invest more time and effort to ensure success. As drivers strive to meet the demand of new industry standards, they will very likely increase their commitment to voluntary simulator training, studying, and BTW training.

All Courses

Control Systems/Dashboard

Basic Control

Visual Search

Distracted Driving

Speed Management

Space Management

Night Operation

Extreme Driving Conditions

Drug and Alcohol Impaired Driving Module

Computer-based Training

Pre-Trip Inspections

Post-Trip Inspections

Combination of Simulator and Computer-based

Hazard Perception

Shifting and Operating Transmissions

Backing and Docking

Need a little more practice time? Schedule time with our CDL simulator!

National Training Inc. is proud to offer CDL Simulator Training for Class A, B, and C training. Gain exposure to real road conditions and build your confidence in a safe, low risk controlled simulation environment. For more information on our CDL Simulators, click here .

“1 hour of simulation training = 4 hours behind the wheel training.”

2 hour simulator intro.

This course must be taken prior to scheduling additional simulator courses.

8 Hour Simulator Package

2 Hour Simulator Intro + 6 Hours of Simulator Training

Simulator Seat Time

*Must complete the 2 Hour Simulator Intro Course prior to scheduling additional seat time.

Class B Simulator/Hands-On Course

National training courses.

Contact us for more information on the various courses we offer.

Our CDL Now training program prepares you for truck driving in 4 weeks. We teach you how to drive in different traffic situations carrying different loads, in different geographical conditions, and under different weather conditions. Our highly trained instructors offer both classroom preparation and hands-on training that you need to safely and properly handle trucks and obtain your CDL Class A license. Click here to learn more!

Class B Fleet and Class C CDL

Our Class B Fleet and Class C CDL courses are customized training classes designed for individuals that are wanting to drive straight trucks, buses or vehicles transporting placarded amounts of hazardous materials. Click here to learn more!

CDL Refresher Course

The CDL Refresher Course is customized training designed for individuals that currently hold a Class A, B or C CDL license and want to refresh their skills as well as those returning to the field. We offer 2 convenient classes tailored to fit your needs. Click here to learn more!

HAZMAT Course

Our Hazardous Materials Course will teach you everything you need to know to pass the written test to add a Hazardous Materials (HAZMAT) endorsement (H) to your CDL. Click here to learn more!

Fleet Entry-Level Driver Training (ELDT)

National Training’s ELDT course is designed specifically for entry-level drivers and ensures they receive the required training and demonstrate proficiency in theory training and behind-the-wheel (BTW) training prior to taking their skills and knowledge tests. Click here to learn more!

Fleet Training A&B

National Training specializes in creating custom group training programs tailored to meet the needs of individual companies and their fleet driver training requirements. We will train, re-train or upgrade the skill levels of your current drivers, and we can train them at your facility or ours. Click here to learn more!

Passenger Endorsement Course

COMING SOON

National Training’s upcoming Passenger Endorsement Course is for drivers who will be carrying 16 or more people, including the driver. Learn all you need to know to pass the exam and skills test. Click here to learn more!

CDL Simulators

Whether you are looking for refresher training, continuing education, skills improvement, or student driver training, our state-of-the-art CDL simulator can provide measurable benefits. Our simulator system provides a low-risk, low pressure way to train both new and experienced drivers and can be used for CDL Class A, B, and C training programs. Click here to learn more!

- CDL Exam Simulator

- NJ Pretrip CDL Exam Simulator - 1

FREE 2024 New Jersey (NJ) Pretrip Exam Simulator 1

2024 nj pretrip information.

The pretrip exam is an oral exam that you will need to pass after you have taken all of your CDL written tests, and are at the exam station for your pretrip, skills, and road test exams. During the pretip exam you will need to verbally check components to make sure that the vehicle is safe for operation. In some states there can be over 100 items to check on a tractor trailer.

The exam doesn’t stop at just listing the components, you will have to name the item by its proper name and say at least 3-5 things you would check that item for. Don’t’ forget to mention what you are going to check the 3-5 things for as well. This is a very detailed exam on the vehicle and its parts be ready.

As an example, the air compressor would need checked, we are going to check belts (if not gear driven), air lines, and securement of the air compressor. Because we mentioned belts (if not gear driven) we have to check for play in the belt, check it for wear, and crack. Moving on the air lines, need to be secure, no breaks or cracks, and no leaks. Finally check all bolts, nuts, and securement pieces to make sure none are loose or missing.

Based on the 2024 NJ CDL Driver's Manual

Questions appearing on this cdl practice test:, when doing the pre-trip, you should tell the examiner each item you are checking and 2-3 things you check each item for., should you do an overview of your vehicle as you approach it (including looking for leaks, leaning, or excessive damage), when checking the lights at the front of the vehicle what should you check for, when checking the windshield, what should you be looking for, when opening the hood, you should check, checking the mirrors on the outside of the vehicle you should check for, in the engine compartment there are four fluids you must check, they are, in the engine compartment there are four major belt or gear driven components. what are they, what should you check each of the fluids in the engine compartment for, what are the main components of the steering controls found in the engine compartment, what should you check the steering linkage for, which of the following does not get checked in the engine compartment, which of the following is not an engine compartment belt, the leaf springs, shocks, u-bolts, shackles, and air bags are part of what system, hoses in the engine compartment should be checked for, the engine belts should be checked for, brake lines should be checked for, air chambers are, air chambers should be checked for, the slack adjuster is part of the braking system, what is the maximum play allowed with the brakes off, brake pads should be checked for, brake drums, brake drums (or discs) must not have cracks longer than:, tire tread depth depends on the axel. the depth should be no less than ______ for the steer axel, and _____ for any other axel., retreaded tires can be on any axel., tires should be checked for, you should check rims for dents, cracks, illegal welds, valve stem, and that they are tight and secure., all rims have a spacer., lug nuts (that hold the rim to the axle) should be checked for, the hub oil seal should be, differences between the steer axel and the rest of the axles are: tread depth, spacers or budding rims, space between the tires, torsion bars, and air bags., you can leave the hood open when moving on with the pre-trip., more new jersey cdl exam simulator: ( indicates current test), general knowledge exam simulator 1, general knowledge exam simulator 2, general knowledge exam simulator 3, general knowledge exam simulator 4, general knowledge exam simulator 5, general knowledge exam simulator 6, general knowledge exam simulator 7, general knowledge exam simulator 8, haz mat exam simulator 1, haz mat exam simulator 2, haz mat exam simulator 3, haz mat exam simulator 4, school bus exam simulator 1, school bus exam simulator 2, school bus exam simulator 3, school bus exam simulator 4, passenger vehicles exam simulator 1, passenger vehicles exam simulator 2, passenger vehicles exam simulator 3, passenger vehicles exam simulator 4, air brakes exam simulator 1, air brakes exam simulator 2, air brakes exam simulator 3, air brakes exam simulator 4, combination vehicles exam simulator 1, combination vehicles exam simulator 2, combination vehicles exam simulator 3, combination vehicles exam simulator 4, combination vehicles exam simulator 5, double/triple trailers exam simulator 1, double/triple trailers exam simulator 2, double/triple trailers exam simulator 3, tanker vehicles exam simulator 1, tanker vehicles exam simulator 2, tanker vehicles exam simulator 3, pre-trip inspection exam simulator 1, pre-trip inspection exam simulator 2, pre-trip inspection exam simulator 3, new jersey free pretrip videos, engine compartment pretrip inspection, inside cab pretrip inspection, rear of tractor pretrip inspection, exterior light pretrip inspection, complete trailer pretrip inspection.

Full Class A CDL Training - 48 Hours

Training program, credential(s) offered.

Government license, Employment

Method of Delivery

When offered.

Daytime Hours, Evening Hours, Weekends

Instructional Program (CIP)

Description.

48 hours of instruction in driving a commercial vehicle spread over eight days. This course is best for people with no experience driving a commercial truck.

Includes one CDL skills exam and one DOT drug test.